How to choose a wall bracket for your TV?

Use our convenient bracket selection modules:

- by make/model of your TV

. click on the link “Select a bracket according to your TV model”

. in the pop-up window, indicate the brand of your TV, then its model

. If desired, you can select additional bracket parameters:

Distance from wall

The module will automatically select all possible options for you. When choosing a bracket, pay attention to the fact that it must fit the diagonal of your TV and support its weight.

- according to the VESA standard of your TV

How to use it correctly?

. go to the section “for LCD and LED”

. click on the link “Choose a bracket according to VESA”

. In the pop-up window, specify the VESA settings of your TV. You can find it in the instructions or measure it yourself. To do this, look at the back panel of the TV: there are 4 threaded holes on it, arranged in a rectangle or square. Measure the distance between them, the resulting numbers are the VESA standard! For example, you get 400 mm in width and 200 mm in height - this means that the VESA standard of your TV is 400x200.

. If desired, you can select additional bracket options.

Bracket function range: swivel, tilt or fixed

Bracket color: black or white

Distance from wall

The module will automatically select all possible options for you. When choosing a bracket, please note that it must fit the diagonal of your TV and support its weight.

If you are unable to find a suitable model, feel free to call us toll-free at 8 800 250 50 51. We answer all your questions from Monday to Friday from 8:30 to 17:30 (Moscow time)

What is VESA?

VESA is the distance between the holes for mounting the bracket on the back of the TV, located in a rectangle or square. You can measure these distances yourself using a tape measure or ruler. For example, you get 400 mm in width and 200 mm in height - this means that the VESA standard of your TV is 400x200.

What functionality should I choose a TV bracket for?

When choosing a bracket, it is important to consider that the functions of the mounting models differ from each other. And depending on the layout of the room and the location of the TV, you should choose a bracket with one or another set of functions.

|

Fixed bracket If you plan to place the TV at a height of 1 - 1.5 meters from the floor and in the future you will watch it from one point, then a fixed bracket will be the best option for you. This mount is ideal for ultra-thin screens, as the TV is installed close to the wall. When purchasing a fixed mount, it is very important to take into account the presence of protrusions and plugs on the back of the TV, which may prevent you from hanging it close to the wall. Please note that you will not be able to tilt or swivel your TV with a fixed arm. |

Side view |

View from above |

What is the minimum distance from the wall and why does it need to be taken into account?

The minimum distance from the wall is the distance between the wall and the TV mounted on the bracket. When choosing a bracket, pay attention to this parameter. It is recommended to measure the length of the plugs and choose a bracket with a slightly larger distance from the wall to avoid bending the wires.

Why can’t you hang a TV on a bracket larger than the maximum allowed diagonal, if the weight and VESA parameters of the TV allow?

If you hang a TV with a diagonal larger than the recommended one on the bracket, you will limit the ability to rotate and tilt the bracket to the angle stated in its technical specifications. It will also be inconvenient for you to hang the TV on a bracket and connect wires to it.

When installing or replacing batteries yourself, there is a need to select related equipment. One of the fastening elements is a bracket, which allows you to securely fix the heating radiator and thereby ensure the proper operation of the entire system. The fastener is a galvanized steel hook with a round or rectangular cross-section, the other end of which has a fastening plate or thread.

- Which retainer is right for you?

- Prices

- Do-it-yourself installation

The correct choice of brackets is very important, since the equipment cannot be allowed to one day sag, collapse from sudden seismic activity or from an accidental impact.

Types and application of radiator holders

Batteries are made of copper, aluminum, cast iron and bimetal (their inner layer is made of steel, the outer layer is aluminum). They are either suspended from the wall or based on floor installations; it is possible to combine these options. Some fasteners can be adjusted in height and length. There are many types of brackets, divided into 2 large groups:

1. Wall:

- pin (anchor) fixed (short and long) holders for bimetallic or steel radiators;

- adjustable in height (change range is about 20 mm) with a mounting plate, they allow you to hide installation errors, surface unevenness, or hang batteries with a large number of sections (more than 6) perfectly horizontally;

- corner - for small or light heating elements.

There are also anti-noise holders with a special coating (rubberized). Technical characteristics of this bracket for mounting radiators: material - steel, diameter - 7 mm, can withstand weight up to 82 kg. They are usually taken for bedrooms so that the slight knocking noise that occurs in the equipment when heating is not heard.

2. Overview of brackets for mounting a floor radiator.

They come in the form:

- an independent stand with a sole, used for massive structures that are impractical to hang, for example, near too thin (plasterboard) partitions or display windows;

- additional for batteries screwed to the wall - these are the most suitable brackets for cast iron radiators;

- a stand with hooks that can be screwed to the floor and to the wall; It is also intended for large equipment, but is used to distribute the load between planes (for example, in a wooden house).

Floor holders can also be height-adjustable. There are options:

- in the form of a stand without fixing the radiator;

- with additional holding elements: with a chain or clamp;

- on a sole or on a tripod, can be screwed to the floor or simply placed on it.

How to choose the right bracket

The main rule when buying a retainer: it must withstand the weight placed on it. The maximum load is usually indicated in the included instructions. It is easiest to choose a bracket for an aluminum radiator, since it weighs little and any type is suitable for it.

For very powerful batteries, use floor stands. But if the covering in the house is wooden, then you need to make sure that the clamps are equipped with additional fasteners to the wall. This is necessary in order to reduce the load on the boards. For light heating elements that will be located in a deep niche under the window, it is better to buy a long bracket.

For cast iron radiators, it is recommended to use holders with the ability to slightly change the height, otherwise installation difficulties may arise. The price of an adjustable bracket is not so high as to give up installation convenience.

It is important that the alloy contains no toxic substances released when heated. You should not buy parts secondhand, especially without the appropriate accompanying documents. Please note that the lightest one - the corner bracket - is intended only for aluminum and copper radiators.

| Brand | Production | Characteristics | Price, rubles/pcs. |

| Omec | Italy | fixed, wall-mounted, anti-noise, steel, up to 70 kg, anti-corrosion galvanized | 130 |

| Conner | China | floor-mounted, to strengthen the lower part of the radiator, uncoated steel, up to 100 kg | 255 |

| Royal Thermo | Italy | for bimetallic batteries, adjustable within 2 cm, up to 70 kg | 170 |

| Tiarun | Russia | anchor, made of galvanized steel, painted with epoxy enamel, length 170, 220 and 250 mm, up to 150 kg | 35, 50, 70 |

| 08ps - GOST1050-88 | angular, made of sheet steel, coated with powder enamel, according to the description, the weight of the bracket is only 52 g / piece, designed for aluminum radiators, up to 50 kg | 25 |

How to do the installation yourself

First, marking is done according to the following rules:

- the distance to the floor and window sill should be about 100 mm;

- For every 6 sections, 2 brackets are placed on top and 1 on the bottom.

Installation of the clamps is simple:

- holes are drilled in the concrete wall, dowels are inserted and threaded holders are screwed into them;

- in brick - the joint is additionally strengthened (hidden) with cement mortar and wait for it to harden;

- fasteners with a special plate are screwed to a wooden surface using nuts;

- if necessary (for cast iron batteries), install a stand on the floor, screwing it carefully;

- All holders are checked for reliability by trying to rotate or move them manually.

Then the radiator is hung on the brackets. After this, the strength of the structure is tested again.

obogrevguru.ru

Choosing brackets for mounting heating radiators: types of fasteners and their calculation

In a radiator heating system, heating devices are traditionally installed under window sills. In exceptional cases, the design may provide for a different arrangement of radiators. To secure heating devices in selected places, special brackets for heating radiators are used, produced by manufacturers in a large assortment. Fasteners suitable for aluminum or bimetallic devices are not suitable for cast iron batteries, which have significant weight and substantial dimensions.

Various types of wall and floor fastening elements for heating devices

Criteria for selecting fasteners

The selection of fastening elements is made taking into account the main technical characteristics of the installed heating system, as well as the characteristics of the room in which installation work is carried out. The following number of factors play an important role:

- battery material;

- overall dimensions of heating devices;

- building material that was used to build the walls;

- the size of window openings, their number in the room and location features;

- room interior design project.

Having objectively assessed all of the above factors, you can choose the right fasteners, as well as calculate their quantity.

Wall mounting method for radiators

This method is most widely used in the practice of installing heating systems. For direct fastening of heating devices to the load-bearing wall of a room, corner and anchor fasteners are available for sale.

Important! When selecting a bracket, adhere to the following rule: the heavier the radiator, the greater the thickness of the fastening element should be. In addition, the materials used to manufacture the fasteners and batteries must match each other.

Fastening cast iron batteries

For massive cast iron radiators, which differ from other heating devices in their greater weight, several types of fasteners are used:

- cast iron holders;

- adjustable steel fasteners that allow you to adjust the distance between the battery and the wall while simultaneously leveling the device in height and strictly horizontal position;

- steel pin brackets;

- holders on a steel strip, etc.

Any standard fasteners are suitable for firmly fastening cast iron batteries to concrete and brick walls. Wall mounting of these heating devices on wooden or plasterboard walls must be accompanied by reinforced floor fastening. In this case, an additional floor bracket for the radiator is purchased, which is designed to take on the bulk of the load.

Fastening of aluminum and bimetallic devices

You will need completely different brackets for bimetallic heating radiators and their aluminum analogues. These heating devices are much lighter than their cast iron counterparts, so they are suitable for mounting:

- steel corner fasteners (simple or reinforced model);

- steel round or molded pin bracket with dowel, the length of which varies between 120-170 mm;

- universal wall fasteners with plastic cover, etc.

Important! Manufacturers of heating devices, as a rule, supply special fasteners that are ideal for a specific radiator model.

Round pin brackets with dowels for aluminum radiators

Floor mounting method

This mounting option is used much less frequently than the wall mounting option. This installation method is chosen either for the sake of reliability and safety (in the case of “fragile” walls), or at the request of the designers. Floor fastening elements are presented as:

- fixed brackets, sometimes they are equipped with a plastic cover;

- adjustable devices, also sometimes included with a plastic cover;

- combined floor fasteners;

- special floor brackets, the width of which is 80 or 100 mm.

Important! Manufacturers offer small legs for some heating radiators.

Using two floor brackets, the radiator is firmly attached to the base

How is the number of fasteners calculated?

You can find out how many brackets are needed for a radiator from the technical documentation regulating construction and installation work. When installing cast iron batteries, they are guided by the rule that: for a device that includes more than two, but less than nine sections, you will need three wall brackets. Two fasteners support the heater from above, and one from below. For aluminum and bimetallic radiators, universal kits are sold, including three pin brackets-sabers, coming with the same number of dowels.

Mounting the Pin Molded Bracket to a Predetermined Location

When installing batteries on floor stands, the latter are calculated as follows:

- two floor holders for batteries with a number of sections not exceeding 10;

- three holders for devices with more than 10 sections.

Important! For heating devices supplied by manufacturers complete with fasteners, the number of the latter is determined by the manufacturer in accordance with current standards.

Every person can choose a bracket for a heating battery and install it independently. Those who are used to trusting the work to professionals will not have to worry about installing fasteners, since the entire installation of the heating system will be handled by a team of specialists.

Video: how to attach heating radiators

teploguru.ru

Brackets for heating radiators

The installation sequence for any type of radiator is the same and practically does not depend on what material the radiator is made of. All the differences lie only in what brackets are used for heating radiators.

Installation of a heating device under a window is carried out in compliance with certain dimensional restrictions: minimum height above the floor is 8-12 cm, to the rear wall 3-5 cm, to the window sill 6-10 cm. The specific location and necessary fasteners (range and quantity) are preliminarily determined. .

Depending on the length, one radiator requires a different amount of fasteners. Practice shows that even for an 8-10 section cast iron radiator, two upper and one lower support holders are quite sufficient. Extending the radiator by 5-7 sections (for cast iron) and 7-10 (for aluminum) automatically increases the required number of fasteners by one upper and one lower.

It is considered best to place the heating device in the center of the window opening. Therefore, calculate the middle and mark the vertical in this place with a level. Further marking depends on the wiring:

- if the wiring is lower, then mark the upper limit of the installation of the heating device (horizontal, parallel to the floor surface);

- if the connection is lateral, then the most important factor is the location of the supply pipe (most often, the top one). Therefore, we mark the horizontal line along the axis of the supply pipe. The distance between the mounting points on the radiator is measured and transferred to the marked horizontal lines. Depending on the type of fasteners used and the type of radiator, markings. In some cases, you will have to apply the fastener itself to the wall.

In order for the installed heating radiator to be secured correctly and securely, it is necessary to select the necessary fasteners.

Types of brackets for mounting radiators

Brackets for cast iron radiators

Bracket for cast iron radiators

First of all, we will consider fasteners for the heaviest heating devices, brackets for cast iron heating radiators. The radiators for these products are also quite massive. As a rule, they are made in the form of separate pins curved in a certain way, or from similar pins, but fixed to a bar.

When choosing supports for cast iron heating devices according to price lists, pay attention to the fact that next to the description there is the word “reinforced”. The pins are painted white or any other (pre-agreed) color upon release.

For each section of different depths, fastening elements are selected taking into account the required size. At the same time, we should not forget that at least 3-5 cm must be left between the back wall of the heating device and the wall.

In addition to standard fasteners for installing cast iron radiators, hooks are available. Retail chains offer them together with a fastening dowel. Installation follows the standard scheme: a hole is drilled in the wall, a dowel is driven into it, into which a hook is screwed.

There is a third version of fasteners - mounting strips designed specifically for hanging cast iron radiators (a vertical plate with two pins for the upper and lower fastening of the section).

The fourth option is to equip the cast iron heating device with legs for installing it on the floor. They can be of two types: with and without height adjustment. The upper arcs, which secure the radiators to the lower stop, also have a different design. They can be made in the form of a chain of several links, or an arc made of wire. The radiator is fixed to the racks with a bolted connection.

Brackets for bimetallic heating radiators

Bracket for bimetallic radiators

Brackets for bimetallic heating radiators (option, Al - radiators). Visually they are very reminiscent of those used for cast iron heating devices, but are less massive.

Brackets for aluminum heating radiators are most often made in the form of corner universal products. The recess for the passage of the collector is made both from below and from above, which allows it to be installed on the left or right.

Radiators made from the material mentioned above are not available in floor-standing versions. But the trade offers a floor bracket for a heating radiator, which allows you to make a floor heater out of them.

The stand is fixed to the floor, then the radiator is attached to it. First of all, floor placement of Al radiators is used in cases where the interior partitions in the room are made of weak materials (aerated concrete, plasterboard, etc.) that do not hold well with any type of fasteners.

The recently fashionable glass walls are also poorly suited for hanging any heating devices. In such options, radiators are completely abandoned, replacing them with warm floors, or floor-standing versions of tubular radiators, or “retro” cast iron ones.

Brackets for steel radiators

Bracket for steel radiators

Fasteners used for installing steel radiators. Speaking about them, it should be remembered that the group is divided into two large subgroups. The first consists of panel heating devices, and the second includes tubular radiators. They require different types of fastenings.

Radiators of the first subgroup have welded brackets (on the wall facing the wall of the building), which allow them to be hung on installed hooks. Brackets for panel heating radiators have a special shape designed specifically for the brackets mentioned above.

The installation of such radiators requires strict control of the vertical placement, because At the same time, at least 4 staples must be placed on the hooks at the same time. That is why, when solving the issue of hanging panel-type radiators, they use not only and not so much the above-mentioned scheme, but standard brackets for panel radiators, a typical representative of which can be called LK-KS 30/50.

Models of components depending on the mounting method

Depending on the chosen mounting method, the required range of components can vary over a wide range. These can be wall-mounted brackets for heating radiators or floor-mounted versions of radiator brackets.

Example: fastening a panel-type radiator. With a small mass of the product, it is enough to simply fix it on the upper brackets, and use stops in the lower part to give the radiator the desired horizontal direction. Such heating devices are attached with a bracket to a hook and simply rest against the wall.

For steel radiators of the second type (tubular), they use their own types of fastenings; these are brackets for heating radiators, which consist of upper and lower elements. The first ones are attached to the wall with dowels and take the bulk of the radiator onto their hook. And the lower ones play the role of stops for the bottom of the radiator.

See also the video “Brackets for fastening sectional radiators to the floor”

Types and methods of installing brackets for heating radiators

Radiator brackets are one of the fastening options when installing a heating system. Fastening elements allow for reliable and safe installation of individual elements of equipment, and also contribute to the effective transfer of heat into the room.

Fastening elements allow for reliable and safe installation of the heating system

When choosing a bracket, it is necessary to take into account all the features of a particular heating system and room.

The following factors should be taken into account:

- structural material of pipes and batteries;

- dimensions of radiators and pipes;

- indoor wall material;

- overall parameters of window openings, their number and location;

- features of the external design of the room.

Only a comprehensive, thoughtful approach will make it possible to correctly select the desired fastening option, calculate the required quantity, and also choose the mounting method (on the wall or on the floor).

Battery wall mount

This installation option is most common and is designed to attach heating system elements to the wall using special brackets. Fasteners are selected for each battery separately, based on the following consideration: the heavier the structure, the thicker the bracket. Therefore, the strength of the bracket must match the weight of the equipment.

Cast iron radiators

Cast iron batteries are characterized by high weight and large dimensions. The following types of brackets are recommended for them:

- adjustable steel fasteners, with which you can adjust the distance between the wall and the radiator, as well as adjust the horizontal position of the battery;

- cast iron fasteners;

- steel pin fasteners (length can reach 300 millimeters);

- fastening on a steel strip, etc.

Close attention should be paid to the material from which the walls are built. If we are talking about a cast iron radiator, then you can use standard brackets. For plasterboard, wooden walls, as well as in the case of other materials with a porous or loose structure, you will need to install brackets on the floor. In this case, the mounting support will take on the main load, and the wall mount will only act as a safety net.

Floor bracket is used for plasterboard and wooden walls

Bimetallic batteries

Fastening elements for equipment on a bimetallic base are selected using the same principles. Although the weight of such structures is less than that of cast iron, the load on the wall can also be considerable. Therefore, if necessary, it is also recommended to use floor supports.

Aluminum batteries

Radiators made of aluminum are lightweight, so they can be installed on walls made of any material.

For both aluminum and bimetallic batteries, the following fasteners are used:

- steel reinforced or corner fastenings;

- steel pin brackets using 120-170 mm dowels;

- standard wall brackets with plastic cover.

Note! For certain battery models, special proprietary fasteners are produced.

Floor mounting of batteries

This method is much less common than the wall method. The main argument in favor of this option is the need to ensure the security of the system, and sometimes also to maintain the design intent. The advantages of floor mounting are the speed of installation, the reliability of the connection, as well as the variety of battery models that can be installed in this way.

A few days ago, my old client, let’s call him Andrey, whose batteries I recently changed, called me with an unusual question.

The crux of the matter was this: he and his friend decided on one's own replace old batteries. They knew in a nutshell how and what was needed for this, and Andrei generally observed my actions when I was working. If there was something unclear, he always asked, and I, without hiding too much, told him in detail the features of the work. But, here’s how to make the markings correctly and make sure that the centers of the radiator and pipe axes coincide - they didn’t pay attention. That's why they turned to me.

To be honest, I never expected this. I didn’t expect that someday someone would need this and would have to explain over the phone how to make the markings. I never thought it was so difficult. Of course, for me everything looks simple: I removed the old battery, marked it, drilled holes, drove brackets into them and hung the radiator. But everything is simple only for me, a person who changes batteries almost every day, like, for example, for each of us to wash our face in the morning

In the evening, Andrey sent a letter of gratitude and photographs of the work done. It turned out great, no worse than mine.

This life episode is firmly embedded in my memory. Probably, Andrey is not the only person who has encountered such a problem. Therefore, I decided to tell you in more detail how I mark and install brackets for aluminum or bimetallic radiators.

I wrote here how to prepare for replacing a radiator, what is needed for replacement and what tools are needed. I won’t repeat myself, but will get straight to the point. Having dismantled the old battery, we will see the following picture:

On a horizontal pipe, unscrew the couplings; if there are no couplings, cut the threads and install transition connections. In this case, replacement is made with polypropylene pipes. I use flax and Unipak paste as a sealing material for carvings.

Now we place the radiator near the window. Some people like it when the radiator hangs in the center of the window, others move it closer to the edge. How exactly to place it is your choice.

Personally, I like it when the radiator hangs in the center.

By the way, the question is often asked: how many brackets are needed for a radiator? Practice has shown that for an aluminum radiator of up to 12 sections, three fastening points are sufficient: two on top and one on the bottom. And if there are more than twelve sections, then four attachment points will be needed. And yet, bimetallic radiators are heavier, so such radiators of up to 10 sections are installed on three brackets. Well, if there are more than 10 sections, then four.

We move the radiator to the side; we won’t need it for now. We take a building level, place it in the center of the horizontal pipe on which the transition coupling was previously installed, and make a mark on the wall. There is no need to calculate the center with a ruler; it is enough to determine it by eye.

Approximately one centimeter below our mark we draw a horizontal line. Brackets will be installed on this line. Why lower? In order for the centers of the radiator and pipe axes to coincide.

Now we draw vertical lines to this line. It will turn out like this:

It remains to note the location of the lower central bracket. We mark 50 cm from the top line and make a mark.

We drill holes, insert dowels and screw the brackets into them. Of course, you can simply hammer in the brackets, because as popular wisdom says: “A hammered self-tapping screw holds better than a twisted nail.”

It is best to choose a flat bracket for the radiator, with a dowel. Unlike other brackets, these allow you to easily adjust the distance of the radiator from the wall and align it in planes.

If necessary, align the radiator by bending the bracket up or down.

When adjusting the radiator, do not forget to monitor the axes of the radiator and pipe, they must be at the same level.

Of course, before hanging the radiator on the brackets, it needs to be “assembled”, i.e. install fittings, taps and adapter couplings.

After all the manipulations, you will get a radiator correctly installed along the axes. Ready for connection and further use, but this is already quite

P.S. Still, replacing heating radiators requires certain knowledge and skills, as well as a set of necessary tools. If you have neither one nor the other, but still have the desire to replace the radiators, you can contact me for help. To do this, just call 903-36-05, send an email [email protected] or leave a request on the Golden Hands website and I will call you back.

The final stage of the roof installation is the installation of the drainage system. Among the various systems, you need to choose the one that suits your requirements - metal with galvanic coating or plastic. Gutter manufacturers offer a full range of components. For information on how to perform the installation itself, read the article.

Calculation of components

Based on the size and shape of the roof, you can independently calculate how many pipes, gutters, brackets and other parts of the drainage system you will need.

Based on the size of the roof, we select the diameter of the gutters:

- If the roof area is less than 50 m2, gutters 100 mm wide and pipes 75 mm in diameter are used.

- Up to 100 m2, 125 mm gutters and 87 mm pipes are used.

- More than 100 m2 - gutters 150 mm and pipes 100 mm (the use of gutters 190 mm and pipes 120 mm is allowed).

In the case of a complex roof structure, gutters and pipes are determined by the largest projection size of the roof part.

The roof area, consisting of parts, is 160 m2. Considering that one drain pipe is enough to service 100 m2 of roofing in projection, for the roof in the example you will need 2 drain pipes located at the corners of the house. The number of funnels corresponds to the number of pipes, i.e. - 2 pieces.

The number of vertical pipes is determined depending on the distance from the cornice to the blind area. Subtract 30 cm from this distance - the height of the drain elbow above ground level.

For example, the height to the cornice is 7.5 m. Then 7.5 m -0.3 m = 7.2 m.

We will need 3 pipes of 3 m each on each side, which means 6 pipes on both sides.

The number of clamps will be 5 for each side (between the elbow and the pipe, between the pipe and the ebb, and between the pipes) and, accordingly, 10 pieces for the entire roof.

Calculation of the number of gutters

The most commonly used gutter size is 3 meters. The length of cornice A and cornice B is 10.3 m. This means we need:

- There are 4 gutters on cornice A (3m + 3m + 3m + 1.3m). This will leave us with another 1.7 m of unused gutter.

- On cornice B there are 3 gutters and the remainder (1.7 m) from cornice A.

- For eaves C and D we use 2 gutters each, that is 4 pieces on both sides.

- In total, 11 gutters of 3 m each for the entire roof.

The number of gutter corners corresponds to the number of roof corners, in our example there are 4 of them.

Calculation of the number of brackets and gutter locks

The brackets are installed at the rate of 1 piece per approximately 50-60 cm. We take 50 cm and carry out the calculations.

Having summed up the numbers in the last column, we find out that in order to attach the gutters, we will need 58 brackets.

The number of locks between the gutters is equal to the number of joints. In our case, this is 16 pcs.

The number of ebbs (marks) is equal to the number of funnels. In this case, you need 2 times more knees for each funnel. Then for 2 funnels you need:

- 4 knees;

- Low tide 2.

If the facade is not level, but has protrusions, you need to purchase elbows to go around it. The figure below will help you determine their number.

List of required items

In total for this drainage system you will need:

- Gutter (3 m) – 8 pcs.

- Gutter (2.5 m) – 2 pcs.

- Gutter (1.3 m) – 2 pcs.

- Gutter lock – 16 pcs.

- Gutter angle – 4 pcs.

- Bracket – 58 pcs.

- Knee – 4 pcs.

- Drain elbow (mark) – 2 pcs.

- Pipe (3m) – 6 pcs.

- Funnel – 2 pcs.

- Clamp (with pin) – 10 pcs.

Pro tip:

Installation of brackets and gutters

Fastening the drainage system begins with marking the installation locations of the brackets using a marking thread.

The center of the gutter should be located below the bottom edge of the roof. The gap between the line (shown in dotted lines in the diagram) of the continuation of the roof and the top of the gutter holder must be at least 25 mm.

The funnel is installed above the storm drain. The funnel must be secured to two brackets or at two points. The location of the funnel can be in the center or at the edge (set in the project). A hole is cut in the gutter using a hacksaw to the size of the funnel.

The brackets are fixed to the gutter line (the slope of the gutter line towards the funnel is from 2 to 5%). The installation pitch of the brackets is from 0.5 to 0.75 m (for selection, use the manufacturer’s “Installation Instructions for the Drainage System”). The extreme bracket is attached at a distance of 25-30 cm from the plug at the end of the gutter. The distance from the corner element to the bracket is no more than 15 cm.

The gutters are inserted into the brackets, starting from the rear, and plugs are installed at the ends. The joints of the gutters are fixed with special locks or connecting elements. The ends of the gutters should be located 50-100 mm behind the side edge of the roof. If the roof span is more than 8 m, an expansion element must be installed between the gutters.

Types of fastening and material of brackets

- The brackets are installed on the rafter leg. Metal brackets are used.

- When using a frontal (gable) board, plastic brackets are used.

- The brackets are attached to the deck using metal extensions. Use plastic or metal brackets.

Possible errors and consequences

- An increased pitch between the brackets leads to sagging of the gutters.

- The mismatch between the edge of the roof and the middle of the gutter leads to overflow.

- Increasing the gap between the gutter line and the edge of the roof - splashing and overflow.

Pro tip:

When cutting gutters and pipes, the use of angle grinders is not allowed, as the coating is damaged and burrs remain. Cutting is done with a hacksaw for metal. It is recommended to clean the cut ends with a file.

Installation of the figured part and drainage pipes

Laying a drain involves installing pipes from top to bottom, with the elbow, coupling and drain installed with the socket towards the top.

Installation is done as follows:

- A piece of straight pipe of at least 60 mm is inserted into the knee-knee joint (depending on the distance between the front board and the wall).

- Next, the necessary shaped part is assembled into which the upper end of the pipe is inserted.

- The system is attached to the wall using clamps, the distance between which is up to 1.8 m. Only one clamp is fixing, the second is a guide. In some systems, the manufacturer recommends the use of clamps - thermal expansion compensators. The clamp is attached under the connector.

- The pipe is positioned strictly vertically using a plumb line.

- A drain elbow is installed at the lower end of the pipe secured with clamps (the lower edge is at a distance of 25-30 cm from the blind area).

- If there is a drainage system or storm drain, then the lower end of the pipe goes there. The pipes are connected using a coupling (connector).

- Each subsequent pipe is inserted into the connector installed on the previous one.

- A clamp is attached under each connection.

- Depending on the design features of the installation site, an elbow of the desired shape or coupling is attached to the funnel. If the roof protrudes beyond the facade, two elbows and a piece of pipe are used. If the roof does not have a protrusion, then use a coupling.

Installation of roof drains is carried out taking into account compensation for thermal expansion. For this function, manufacturers use expansion gaps. Thus, pipe connectors in some systems have installation lines. The edge of the pipe is set along these lines depending on the air temperature at the time of installation. Silicone-treated seals allow elements to slide smoothly during expansion. When using a pipe connector, leave an air gap of at least 0.6-2 cm.

Pro tip:

It is not recommended to assemble the drainage system at temperatures below -5.

This completes the installation of the drainage system. It is necessary to audit all installed elements. If the configuration of the drainage system fully complies with the design, is calculated and installed in accordance with the manufacturer’s recommendations, then all the water falling on the roof will exit only through the pipes, without splashing or overflowing over the edges of the gutters.

At the end of each season, it is advisable to inspect and flush the system (using a hose with water). When clearing any obstructions (leaves, debris), do not use sharp metal objects.

Threaded bracket.

A bracket for radiators is a specific fastening element that allows you to fix the heating element in the right place and in the right position. In this case, the position of the radiator should not change over time and under the influence of increased operating loads. Today you can find both specialized fasteners, for example, a bracket for a cast iron radiator, and a unified device.

The latter, according to manufacturers, allows you to correctly and firmly fix any type of heating device. In practice, experts still recommend buying devices that take into account the characteristics of each specific battery model and their construction material.

Choosing a bracket for a cast iron radiator

Adjustable floor bracket K 11.3.

The bracket for a cast iron radiator must be of increased strength and size. The design of the fastening element is influenced by the parameters of the heating element itself. ) heavy and massive among all types of radiators.

To fix cast iron heating devices, the following types of clamps are used:

- cast, cast iron;

- steel pins 300 mm long with dowel;

- steel with stripes;

- steel with the ability to adjust the horizontal position and distance from the wall.

The choice of fastener is also influenced by the structural material of the wall. So, for a brick and concrete wall, a pin fastening is suitable. Devices with up to 10 sections are mounted on the wall using two brackets at the top and one at the bottom. A heating device with more than 10 sections in size requires additional support using floor clamps and stands. For installation on soft wall materials (plasterboard and wood), only floor fasteners are suitable. It can have a height adjuster or be produced without it.

The bracket for a cast iron battery must be reinforced. This is evidenced by the corresponding inscription on the packaging with the mount - “reinforced”.

Fixing bimetallic radiators

Floor plastic bracket for bimetallic batteries.

Brackets for bimetallic radiators are selected based on the dimensions of the equipment, the number of sections, installation options and features of the structural material of the walls. Compared to cast iron batteries, bimetallic counterparts weigh much less. This type can be mounted directly on a wall (brick or concrete) using universal brackets with dowels. For a plasterboard base, a floor option with adjustable and non-adjustable height (center distance 200, 350, 500) is more suitable.

If the room has a panoramic window and is selected for heating the room ) , then they can be fixed in the desired position using either floor fasteners or a steel corner product. Brackets for bimetallic radiators must be made of steel.

Fixing the steel heater

Adjustable floor bracket K 11.9.

Although steel heating equipment is heavy, it is not as massive compared to cast iron counterparts. That is why the bracket for may have a welded structure. A U-shaped and K-shaped element made of steel is suitable here. It is attached to the wall and is used if the panel heater is equipped with special brackets.

In front of the panoramic window, a bracket for floor-mounted steel radiators would be relevant. But in this case it must have a reinforced structure. If the heating device is large in size, then additional fixation is used for its installation using an angle bracket. Two types of fasteners: wall (rod with dowel or steel with plate) and floor, adjustable stand are useful when the structural material of the wall is not durable. This could be wood or porous bricks.

Aluminum batteries and their fastening

Bracket for lightweight aluminum radiator.

This type of heating elements is the lightest. However, at the same time, its structural material has a high coefficient of thermal expansion. These parameters must be taken into account when choosing a bracket for an aluminum radiator.

Pay attention to the following types of fasteners:

- steel corner. Depending on the size of the heating equipment, it can have a simple or reinforced design;

- round or flat pin with dowel for batteries with different center distances;

- universal with plastic cover;

- floor adjustable fasteners.

In order not to disturb the design of the room, manufacturers of fasteners have developed special models that allow the battery to be fixed using brackets welded to its rear panel.

To organize a heating system along a panoramic window, floor stands or a corner bracket for an aluminum radiator would be suitable.

Features of the wall mounting system

Any bracket for a wall-mounted radiator is a crescent-shaped hook. The loop itself can be made in the form of a semicircle or have a rectangular shape. At the end of the fixing device there can be either a fastening plate (it sits on self-tapping screws), or in the case of a pin fastener, it is a regular thread. With its help, the pin is screwed into the wall, where the dowel is previously inserted.

The bracket for attaching the radiator to the wall can be of the following types:

- cast iron (used only for fixing batteries made of similar structural material);

- steel, pin fixed (used for fixing cast iron, aluminum and steel heating elements);

- steel adjustable element (cast iron, steel, bimetallic heating devices);

- plate retainer made of steel (cast iron, steel batteries);

- corner regular or reinforced structures (for aluminum and bimetallic products).

The bracket for a panel radiator is often shaped like a hook. It secures the heating device through a special bracket that is welded to its rear panel. From a design point of view, this is the most successful installation method, as it is absolutely invisible.

Advantages of floor fasteners

A bracket for floor mounting of a radiator will come to the rescue if the structural material of the wall is not able to withstand the weight of the battery, and therefore the wall clamp cannot be used. The above device is used when installing a heating element opposite a panoramic window. A floor clamp can be an excellent decorative element when decorating a room.

It is used to support particularly massive heating appliances made of cast iron, or to install very large radiators. Installing brackets for floor-mounted radiators will ensure reliable fixation of the equipment. During the work you will not need the help of a specialist, since the device is easy to use.

The following types of floor clamps for batteries are distinguished:

- fixed and adjustable, possibly with a plastic lining;

- combination product;

- specialized, the width of which ranges from 80 mm to 100 mm.

Professional installation of radiators

Reliable installation of any heating element of a heating system depends on how correctly the bracket is selected and how competently and firmly it is fixed. All work must be carried out in strict accordance with the provisions of SNiP of 2003 on heating, ventilation systems and air conditioning of premises.

How to mark brackets for a heating radiator? To correctly answer this question, experts offer the following calculation scheme and detailed photos.

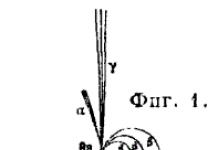

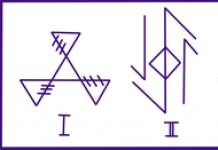

The following conventions are used in Figure 1:

In a similar way, the location of the fasteners and the distance between the radiator brackets are established. Many people ask how many brackets are needed for a radiator? If we are talking about an aluminum heating element, then for 12 sections you need 3 wall fasteners. One below and two above. When the number of sections exceeds 10 pieces, 4 fasteners are used, two at the bottom and two at the top. Bimetallic radiators are heavier, and therefore for 10 sections you need 3 brackets, and if the number of sections is more than 10, then 4 clamps.

Cast iron radiators are considered the heaviest, and therefore require the most brackets to secure them. So, here floor brackets-stands must be used. The number of brackets per radiator increases with the size of the heating element.

The main thing is to secure it correctly

Reliable fixation of the battery depends on correctly selected and installed brackets. Thus, today wall and floor clamps are used, which in terms of shape and strength take into account all the features of heating equipment. The dimensions of the brackets for radiators are selected according to the size of the sections of the heating device.

The structural material must correspond to the loads that will act on the fastener throughout its entire service life. For cast iron radiators, cast iron and reinforced steel clamps are suitable. For bimetallic and aluminum batteries, in addition to the above, corner fasteners are also used. Steel radiators also require reinforced fixation. This video will help you on how to properly mount brackets for radiators: