In apartments built by the hands of Soviet workers, as in some modern buildings, cast-iron heating radiators are installed. These elements do not always fit into the overall interior of the room - in this situation, you need to think about how to cover the radiator with plasterboard and not reduce the level of heat transfer.

According to the existing housing code and redevelopment rules, heating systems cannot be hidden directly in the wall. But you can cover them with an additional wall made of an alternative material.

How to hang a battery - on drywall and a removable screen

Finishing batteries with plasterboard is more often used - this material allows you to quickly and easily hide the flaw in the room and make the appearance more attractive.

Marking

Marking of the future structure is carried out using:

- measuring tool– tape measure, ruler, corner;

- drawing tool– a simple pencil, marker;

- precision instrument– construction or laser level.

When carrying out this stage, it is advisable to adhere to exact dimensions, limiting yourself to whole centimeters. Millimeters are used only in the case of a particularly precise design, for example, for an established interior design.

Before you cover the battery with plasterboard and get rid of its unpleasant appearance, you need to decide which sealing method to use for marking:

- the box is a simpler and faster method of work (only the battery area and, literally, 12-20 cm beyond it are sealed);

- wall - a more labor-intensive method (the wall in which the radiator is installed is completely sealed; if the heating device is installed near a window, it is necessary to make slopes).

In terms of the scope of work, sealing batteries using the first method is simpler: less material is used and a small number of construction processes are carried out. In the second case, even fewer construction processes are used, but more material is used.

Box

When installing a box, the structure takes up little space, covering a little more space than the radiator itself. The depth of such a box depends on the width of the heating device (most radiators are narrower than batteries with metal plates).

Note! The edges of the structure must protrude beyond the edge of the radiator by at least 10 cm - otherwise it will not be possible to install a removable screen on the front side.

Instructions for marking the box:

- Depending on the required position of the structure, a horizontal strip is drawn. If the box will hang, measure the distance from the floor and use a level to draw a marking line. If the structure rests on the floor, there will be 3 lines (two at the edges - depth, one in front - the edge of the structure).

- It is necessary to install a corner to the bottom edge and draw vertical marks - we achieve a right angle. Using a level, we bring the vertical lines to the required size.

- Identical marks are marked on the vertical lines, between which a connecting segment is drawn.

The result should be a square or rectangle (if supported on the floor, additionally mark the base).

Wall

Analyzing the room and thinking about how to cover radiators and pipes with plasterboard and do it correctly, the decision to install an alternative wall comes naturally.

The essence of the solution is that the entire surface to which it is attached is covered along with the radiator. This method is wasteful, since you can get by with small volumes of material by arranging a point box. But a wall is the only way to completely hide a heating device from a room with your own hands.

To construct the wall, the frame is built to the entire height of the room:

- Using a level, several vertical lines are drawn on the base for the frame. Step – 60-100 cm. Lines for profiles in the corners of the room are required.

- From each vertical line it is necessary to extend to the floor. A corner is used for this. The depth of the floor lines is equal to the width between the main wall and the alternative one.

- Similar to the floor lines, lines are drawn on the ceiling - of equal depth and strictly parallel.

- The last marking lines are drawn at the top and bottom of the heating device, at a distance of 7-10 cm.

There are also markings on the sides of the radiator - along the perimeter of the device, profiles are needed in which the removable screen will be installed. But to get rid of unnecessary work, you can make basic markings (which span the entire height of the room) directly on the sides of the radiator.

Frame structure

Before covering the heating radiator with plasterboard, decorating the interior of the room with this, you need to build a frame. For its construction, channel-shaped metal profiles with a width of 60-70 mm are used.

In total, during the work process you will need:

- profiles - as the main frame;

- screws (40-60 mm) – fastening the structure;

- dowels (40-60 mm) – fastening to the surface;

- metal scissors - for making cuts, if necessary, bending metal;

- pliers, screwdriver, drill or hammer drill are auxiliary tools.

The profiles that are adjacent to the wall are attached first.

On our website you can watch a lot of videos on the topic of installing frames for drywall, but the basic instructions are as follows:

- the metal profile is placed on one side or the center to the marking line;

- a screwdriver leaves a small mark on the wall;

- a puncher makes a hole to fit the size of the fastener;

- a dowel is inserted into the hole made;

- a profile is attached to the prepared place;

- a screw is used to secure it.

After placing the metal against the wall, marks are made in increments of 15-25 cm. The holes are prepared for the entire profile at once.

The described process is used to attach all the necessary parts of the frame. In the case of fastening a corner of two elements, you need to trim the necessary parts with metal scissors.

When the parts that are attached to the wall are installed, we move on to the depth of the frame:

- cut parts of profiles of the required size;

- cut both edges of the element by 4-5 cm at the bend;

- bend the middle down and cut the sides to the width of the profile channel flange;

- We attach the sections to the edges of the main long elements at an angle of 90 degrees towards the room.

The last part is the connecting upper and lower short parts, elements.

Note! When constructing a wall covering the battery, long vertical metal elements are used, so two short ones on top and bottom are not enough - at least 4-5 pieces are needed.

The finished frame should be a strong structure and not wobble. If the frame is wobbly, it means that the fastening was not done well, or there are not enough additional short elements.

Installation of the structure

The most difficult stages of solving the question of how to cover a heating radiator with plasterboard and not deprive the room of heat are left behind. If everything is prepared, installation is a simple procedure.

Fastening drywall is carried out according to the following method:

- a sheet of material is attached to a metal base;

- a drawing tool marks the place of the cut - this is how the material is marked into the necessary pieces;

- the prepared part is attached to the corresponding part of the frame and secured with a screw.

The pitch of the screws when fastening the material in the battery box is 10-15 cm; an example of the location of the fastening elements can be seen in the photo above.

It is better to prepare and attach one part of the material at a time; if you prepare everything at once, you can make a mistake because of the corners protruding in some places.

Note! When screwing in a screw, it is important to be careful - if you place the fastener too deeply, you can damage the front side of the drywall.

The removable screen should cover the radiator for ventilation and heat transfer into the room. Its first part, the inner one, is attached to the metal before working with drywall. Then the main material is arranged, and the last step is to put on the removable, outer part of the screen.

Finishing work

When considering how to cover a radiator in a room with plasterboard and not spoil the interior, it is important not to use radically new colors. The best option is to decorate a box or an alternative wall in the general colors of the room. But first you need to prepare the surface for final finishing.

The finishing process proceeds according to the following principle:

- Sealing seams between parts of drywall (see also article about). To do this, a small piece of sickle mesh is placed on the seam, then the joint is covered with putty.

- Sealing the fastening element. It is carried out using a similar method - serpyanka and putty.

- Puttying the entire structure (see also article). Using spatulas, the entire surface of the product is puttied, be it a box or a wall. When the mixture dries, it is leveled by sanding with fine sandpaper.

The final stage is the finishing of the product - often painting or wallpapering. It is better to use the material that is more consistent with the overall interior of the room, if its price, of course, is within the intended budget.

In apartments built by the hands of Soviet workers, as in some modern buildings, cast-iron heating radiators are installed. These elements do not always fit into the overall interior of the room - in this situation, you need to think about how to cover the radiator with plasterboard and not reduce the level of heat transfer.

According to the existing housing code and redevelopment rules, heating systems cannot be hidden directly in the wall. But you can cover them with an additional wall made of an alternative material.

How to hang a battery - on drywall and a removable screen

Finishing batteries with plasterboard is more often used - this material allows you to quickly and easily hide the flaw in the room and make the appearance more attractive.

How to attach a battery to drywall - marking stage

Marking of the future structure is carried out using:

- measuring tool– tape measure, ruler, corner;

- drawing tool– a simple pencil, marker;

- precision instrument– construction or laser level.

When carrying out this stage, it is advisable to adhere to exact dimensions, limiting yourself to whole centimeters. Millimeters are used only in the case of a particularly precise design, for example, for an established interior design.

Before you cover the battery with plasterboard and get rid of its unpleasant appearance, you need to decide which sealing method to use for marking:

- the box is a simpler and faster method of work (only the battery area and, literally, 12-20 cm beyond it are sealed);

- wall - a more labor-intensive method (the wall in which the radiator is installed is completely sealed; if the heating device is installed near a window, it is necessary to make slopes).

In terms of the scope of work, sealing batteries using the first method is simpler: less material is used and a small number of construction processes are carried out. In the second case, even fewer construction processes are used, but more material is used.

Radiator box

When installing a box, the structure takes up little space, covering a little more space than the radiator itself. The depth of such a box depends on the width of the heating device (most radiators are narrower than batteries with metal plates).

Note! The edges of the structure must protrude beyond the edge of the radiator by at least 10 cm - otherwise it will not be possible to install a removable screen on the front side.

Instructions for marking the box:

- Depending on the required position of the structure, a horizontal strip is drawn. If the box will hang, measure the distance from the floor and use a level to draw a marking line. If the structure rests on the floor, there will be 3 lines (two at the edges - depth, one in front - the edge of the structure).

- It is necessary to install a corner to the bottom edge and draw vertical marks - we achieve a right angle. Using a level, we bring the vertical lines to the required size.

- Identical marks are marked on the vertical lines, between which a connecting segment is drawn.

The result should be a square or rectangle (if supported on the floor, additionally mark the base).

How to cover batteries with plasterboard - wall construction method

Analyzing the room and thinking about how to cover radiators and pipes with plasterboard and do it correctly, the decision to install an alternative wall comes naturally.

The essence of the solution is that the entire surface to which it is attached is covered along with the radiator. This method is wasteful, since you can get by with small volumes of material by arranging a point box. But a wall is the only way to completely hide a heating device from a room with your own hands.

To construct the wall, the frame is built to the entire height of the room:

- Using a level, several vertical lines are drawn on the base for the frame. Step – 60-100 cm. Lines for profiles in the corners of the room are required.

- From each vertical line it is necessary to extend to the floor. A corner is used for this. The depth of the floor lines is equal to the width between the main wall and the alternative one.

- Similar to the floor lines, lines are drawn on the ceiling - of equal depth and strictly parallel.

- The last marking lines are drawn at the top and bottom of the heating device, at a distance of 7-10 cm.

There are also markings on the sides of the radiator - along the perimeter of the device, profiles are needed in which the removable screen will be installed. But to get rid of unnecessary work, you can make basic markings (which span the entire height of the room) directly on the sides of the radiator.

Metal frame under the wall

Before covering the heating radiator with plasterboard, decorating the interior of the room with this, you need to build a frame. For its construction, channel-shaped metal profiles with a width of 60-70 mm are used.

In total, during the work process you will need:

- profiles - as the main frame;

- screws (40-60 mm) – fastening the structure;

- dowels (40-60 mm) – fastening to the surface;

- metal scissors - for making cuts, if necessary, bending metal;

- pliers, screwdriver, drill or hammer drill are auxiliary tools.

The profiles that are adjacent to the wall are attached first.

On our website you can watch a lot of videos on the topic of installing frames for drywall, but the basic instructions are as follows:

- the metal profile is placed on one side or the center to the marking line;

- a screwdriver leaves a small mark on the wall;

- a puncher makes a hole to fit the size of the fastener;

- a dowel is inserted into the hole made;

- a profile is attached to the prepared place;

- a screw is used to secure it.

After placing the metal against the wall, marks are made in increments of 15-25 cm. The holes are prepared for the entire profile at once.

The described process is used to attach all the necessary parts of the frame. In the case of fastening a corner of two elements, you need to trim the necessary parts with metal scissors.

When the parts that are attached to the wall are installed, we move on to the depth of the frame:

- cut parts of profiles of the required size;

- cut both edges of the element by 4-5 cm at the bend;

- bend the middle down and cut the sides to the width of the profile channel flange;

- We attach the sections to the edges of the main long elements at an angle of 90 degrees towards the room.

The last part is the connecting upper and lower short parts, elements.

Note! When constructing a wall covering the battery, long vertical metal elements are used, so two short ones on top and bottom are not enough - at least 4-5 pieces are needed.

The finished frame should be a strong structure and not wobble. If the frame is wobbly, it means that the fastening was not done well, or there are not enough additional short elements.

Sheathing batteries with plasterboard

The most difficult stages of solving the question of how to cover a heating radiator with plasterboard and not deprive the room of heat are left behind. If everything is prepared, installation is a simple procedure.

Fastening drywall is carried out according to the following method:

- a sheet of material is attached to a metal base;

- a drawing tool marks the place of the cut - this is how the material is marked into the necessary pieces;

- the prepared part is attached to the corresponding part of the frame and secured with a screw.

The pitch of the screws when fastening the material in the battery box is 10-15 cm; an example of the location of the fastening elements can be seen in the photo above.

It is better to prepare and attach one part of the material at a time; if you prepare everything at once, you can make a mistake because of the corners protruding in some places.

Note! When screwing in a screw, it is important to be careful - if you place the fastener too deeply, you can damage the front side of the drywall.

The removable screen should cover the radiator for ventilation and heat transfer into the room. Its first part, the inner one, is attached to the metal before working with drywall. Then the main material is arranged, and the last step is to put on the removable, outer part of the screen.

When considering how to cover a radiator in a room with plasterboard and not spoil the interior, it is important not to use radically new colors. The best option is to decorate a box or an alternative wall in the general colors of the room. But first you need to prepare the surface for final finishing.

The finishing process proceeds according to the following principle:

- Sealing seams between parts of drywall (see also the article on puttying drywall seams). To do this, a small piece of sickle mesh is placed on the seam, then the joint is covered with putty.

- Sealing the fastening element. It is carried out using a similar method - serpyanka and putty.

- Puttying the entire structure (see also the article How to putty drywall - choosing putty and technology for its application). Using spatulas, the entire surface of the product is puttied, be it a box or a wall. When the mixture dries, it is leveled by sanding with fine sandpaper.

The final stage is the finishing of the product - often painting or wallpapering. It is better to use the material that is more consistent with the overall interior of the room, if its price, of course, is within the intended budget.

Heating radiators and connections to them often spoil the interior of a room. Especially if the room has old cast iron radiators, completely devoid of any aesthetic appeal. Therefore, it is understandable that the owners want to hide these elements of the heating system without compromising the quality of their work. It is logical to use an easy-to-process and affordable material for these purposes - drywall. How to cover pipes with plasterboard? How to hide radiators so that this does not affect their heating performance?

Design options

Before covering the battery with plasterboard, you should analyze the specific placement of radiators and piping in the room. Depending on their location, you can choose one of two options for using drywall:

- A gypsum plasterboard box with a decorative grille covering the battery.

- A false wall that hides radiators and connections to them behind its surface.

Options demonstrating how to cover a battery with your own hands using drywall are presented in the photo below. Both methods have their advantages and disadvantages:

- The installation of the box has the advantage of having less material required. But such a design will not always fit organically into the interior of the room. In addition, you will have to build your own boxes for the pipes, which will further complicate the task. In addition, the presence of such protrusions will seriously interfere with the installation of suspended ceilings or laying laminate flooring.

- The construction of a decorative wall will require more material consumption, but will allow you to obtain a flat surface that can be easily finished in accordance with the overall design of the room. In most cases, such a structure is even easier to build than the box that covers the battery.

Construction of the box

This plasterboard structure can be fixed to the floor or suspended with a gap above its surface. The first option is preferable - the frame has two planes for support, which makes it stiffer.

When designing the box, it should be taken into account that for normal operation of the device, a gap of at least 10 cm is required between the radiator and the surface of the drywall.

- Using a level (preferably a laser) and a tape measure, markings are carried out. The boundary of the upper edge of the structure is drawn on the wall, and perpendiculars are lowered from it to the floor. Using a square, lines are laid to the depth of the box. By connecting them, you get a lower border on the floor. As a result, you get two rectangles - on the floor and on the wall.

- The guide profile is secured along the lines with dowel nails in increments of 15–20 cm.

- Protruding vertical posts are made from a profile, bending it at an angle of 90˚. First, the side shelves are cut on the parts using metal scissors and bent. The bend points can be fixed using “bugs” (small screws for metal), or it is better to use a cutter.

There is an opinion that fastening with a cutter is not strong enough. However, when using a professional tool, the connection is not only very reliable, but also has the advantage of having no protruding parts, which is inevitable when using “bugs”.

- The required number of horizontal jumpers is installed. The more there are, the more rigid the structure. For a drywall box, 1-2 for each of the planes, with the exception of the front one, is quite enough.

- Parts of a decorative grille or removable screen are attached to the frame.

It is necessary to create a strong structure; any vibrations of the frame after installation are unacceptable.

- At the final stage, strips of plasterboard are cut to actual dimensions and secured with self-tapping screws every 25 cm. Subsequently, the plasterboard is puttied, and the finishing is carried out in accordance with the overall interior of the room.

Installation of false walls

It is advisable to erect a decorative wall if, in addition to masking the radiators, you need to decide how to cover the heating pipes with plasterboard. With this method, not much space is lost, but the appearance of the room gains very significantly.

At the first stage, markings are made:

- The profile fastening lines are marked on the wall. They should be spaced at 60 cm intervals in order to join sheets of drywall on them. In addition, two outer guide profiles are attached at a distance of 30 cm from the corners.

- Additional guides will be required if there is a window on the wall: they will be useful for attaching slopes. It is advisable to place a couple more profiles at a distance of 10 cm on each side of the radiator - for mounting a decorative grille.

- Using a square, the marking lines are transferred to the floor and ceiling; their length is the distance from the most protruding part of the radiator (usually a faucet) to the wall plus 10 cm.

In the design of the decorative wall, it is necessary to provide technological openings for access to taps and other parts of the pipeline for preventive maintenance or inspection. Such inspection hatches are subsequently decorated with a fine finish and become invisible in the overall interior.

After marking, the frame is assembled. Its installation is not fundamentally different from assembling a box or other structure made of plasterboard, so there is no point in detailing the sequence of operations. The metal frame for the false wall will differ from the box design in the large number of horizontal jumpers. They are needed not only for joining sheets of drywall, but also for adding rigidity. Experts recommend installing these elements every 60 cm, securely attaching them to the racks using self-tapping screws or a cutter.

Elements cut from plasterboard are attached to the frame. When deciding how to cover heating radiators in an apartment with plasterboard, you should choose a moisture-resistant gypsum board: such a wall will not suffer from condensation forming on the pipes or from possible leaks of the heating system.

How to cover a battery with drywall with your own hands (7 photos)

How to cover a battery with drywall yourself: photo. Design options, their advantages and disadvantages. Installation of the box, construction of a decorative wall.

Communities › Construction (and everything connected with it) › Blog › Covering the battery with drywall

Friends, good day.

I decided to cover the radiator in the kitchen with plasterboard. The kitchen area is quite large, allowing you to implement the idea without much damage to the space. And the presence of individual gas heating in the apartment and not too severe winters allow you to lose some of the heat from the battery without compromising the overall temperature in the apartment.

To begin with, I dismantled the old window sill and began to build a frame around the battery using ceiling metal profiles.

For rigidity, I additionally strengthened the long horizontal crossbars.

After assembling the frame, I installed the window sill, covered the frame with plasterboard and began to putty the structure.

After filling and cleaning, I painted the box along with the walls with water-based paint in two layers. That's what came out of it.

After that, I installed the decorative grille.

For normal heat exchange of the battery, I made holes in the window sill and installed ventilation grilles.

The end result looked like this.

The battery dissipates heat well, there is a flow of warm air from the ventilation holes, and the windows do not sweat.

Professionals, don't kick too hard. I did it for the first time, I already know all the mistakes))

P.S. I made a similar entry in another community, but it was deleted there due to inconsistency with the topic, so I posted the entry here. For those who have already read it, don’t grumble))

Cover the battery with plasterboard

Friends, good day. I decided to cover the radiator in the kitchen with plasterboard. The kitchen area is quite large, allowing you to implement the idea without much damage to the space. And the presence of individual gas heating in the apartment and not too severe winters allow you to lose some of the heat from the battery without…

How to cover a battery with drywall

- Some features

- Additional recommendations

- How the frame works: nuances

Many old apartments and modern houses are equipped with heating radiators made of cast iron. Very often these devices do not fit into the overall interior of an apartment or building. To correct the situation, you need to solve the problem of how to cover the battery with plasterboard so as not to reduce the degree of heat transfer.

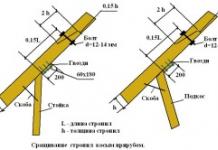

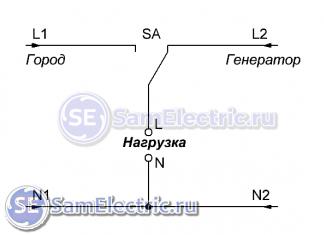

Screen diagram for radiator.

According to the redevelopment rules and the housing code, it is prohibited to hide the heating system directly in the wall. It is allowed to make an additional closing wall for them from a suitable material.

Some features

In most cases, drywall is used to finish the battery. This material makes it possible to hide the lack of space and create a beautiful appearance. Before installation, markings of the intended structure are made. A variety of tools are used for this, from a simple tape measure to a laser level.

When marking the structure, you need to take precise measurements in centimeters. Millimeters are needed if a very precise design is being made, for example, to fit an existing interior. Before covering the battery with plasterboard to create a beautiful appearance, it is necessary to determine what kind of sealing it will be and do measuring work according to this method. The simplest and fastest way is to make a box. This method is used when you only need to seal the battery itself and 20 centimeters beyond it.

The most labor-intensive method is the wall. In this case, the entire wall where the radiator is located is completely sealed. For the battery near the window you need to make slopes.

Finishing using the box method requires the least amount of work.

Screen frame drawing.

A small amount of material will be needed; the construction process consists of several operations. For the second case, much more building material will be required. The box design requires little space. It simply covers the radiator and a small area next to it. The depth of such a box is calculated based on the existing width of the radiator. Basically, radiators are much narrower than batteries made of metal plates.

In accordance with the location of the structure, a horizontal strip is drawn. In the case of a hanging box, you need to measure the gap from the floor using a level and draw a marking line. For a structure mounted on the floor, you will need 3 lines. Two of them will determine the depth, and one will determine the edge of the structure.

To get a right angle, you need to attach a corner to the bottom edge and draw vertical lines. Using a level, draw vertical lines until the required size is obtained. Marks are made on these lines, between which a connecting line is drawn.

After completing the drawing work, you will get a geometric figure, most often a square, sometimes a rectangle. If the support is placed on the floor, it is necessary to make additional markings of the base. After an analysis of the room, the correct decision to cover the radiator and heating pipes with plasterboard can be made without difficulty. Basically, it is necessary, together with the battery, to cover the entire surface where it is installed. This method is not the best solution, as it will require a lot of material. The point box will require small amounts of material. Note that a wall is not the only way to completely cover a radiator with plasterboard yourself.

Screen installation diagram.

To mount a wall, the frame must be the same size as the height of the room. First, using a level, several lines are made, in 60 cm increments, marking the base of the frame. It is imperative to draw the lines intended for the profile in the corners of the apartment.

To continue the vertical line to the floor, you need to use a corner. The depth of the floor lines is equal to the width between the new and old wall. Lines on the ceiling are drawn in the same way. They must be parallel and of the same depth. The final marking lines at a distance of 10 cm should be drawn at the top and bottom of the radiator. The sides of the radiator must also have markings. Profiles must be installed around the radiator to accommodate the removable screen. To avoid unnecessary work, you can make basic markings right on the sides of the radiator.

How the frame works: nuances

Before covering the battery with plasterboard, making the interior more attractive, a frame is built. It is made from 60 channels. For installation, you will need a variety of tools, for example, a hammer drill, scissors for cutting metal, and so on.

First, profiles are attached that are completely adjacent to the wall. The construction technology is performed in the following sequence:

- A metal profile (channel) is installed to the marking line.

- Using a screwdriver, a small notch is made on the wall.

- Using a hammer drill, make a recess corresponding to the size of the fastener.

- A fastener, such as a dowel, is placed in the hole made.

- The profile is attached to the already prepared place.

- Self-tapping screws are used to fasten the profile.

Markings for metal placed against the wall should be made in 15 cm increments. Holes for the installed profile are immediately made. Using the technology described above, all the necessary parts of the frame are fastened. When it is necessary to secure a corner consisting of several elements, the necessary parts are trimmed with scissors for cutting metal.

After complete installation of all parts attached to the wall, the depth of the frame is made. First, the necessary parts of the profile are prepared and cut to the required size. The edges of the parts at the bends are trimmed by several centimeters. Then the middle of the profile is bent down, the sides are cut to the size of the width of the profile flange. At an angle of 90 degrees, to the edges of the longest parts, the made segments are fixed. The final operation of making the frame is to connect all the frame parts together.

The frame must have a strong structure and not wobble. If this occurs, it means that the fastening is poorly made or too few additional small elements are installed.

Drywall sheets are attached to the manufactured frame, which are pre-cut to the appropriate size.

How to cover a battery with drywall with your own hands: features (photos and videos)

How to cover a battery with plasterboard so as not to reduce the degree of heat transfer? According to the redevelopment rules and the housing code, it is prohibited to hide the heating system directly in the wall.

How to cover pipes and radiators with plasterboard

When creating the interior design of their home, every owner dreams of making it comfortable, attractive and unusual. But there is one nuance - cast iron radiators, which catch the eye, especially if the apartment is decorated in the latest fashion. Let's look at how to cover a battery with drywall yourself.

To give the room a modern look, it is enough to build a beautiful plasterboard screen. It will hide the old and unsightly battery from prying eyes. It is worth noting that the work can be done with your own hands, and the cost of materials is low. Some ordinary people doubt whether it is possible to cover batteries with drywall. Let's consider this issue in detail.

Options for hiding heating pipes in the interior of an apartment

There are many ways that help disguise heating devices in an apartment without interfering with maintaining a comfortable temperature in the room.

You can order radiators with an individual design, but this method is quite expensive and not available to a wide range of consumers.

If your family’s financial capabilities do not allow this, then you can cover the radiators with a simple screen. There are several options for such devices:

- buy and attach a hanging screen to the radiator;

- create a wooden element that is mounted above the radiator;

- build a box from plasterboard that will disguise the battery.

If we consider the last option, then it is the most popular. This is due to the ease of assembly and inexpensive material used for the structure. But this method cannot be called perfect, since in case of unexpected breakdowns or leaks, the box will have to be completely dismantled.

Hinged screen for battery

Hinged screen for battery

Before constructing the structure, a thorough inspection of the heating system should be carried out. Check how reliable the joints and connections are. If the pipes are old, then it is better to replace them; the old battery must be replaced if it is unreliable. Only after repairing the heating system in the apartment can you begin work on creating a screen for the radiator from plasterboard.

There are parameters that a plasterboard structure must meet to mask a heating radiator:

Important! Some apartment owners completely cover the batteries with gypsum board sheets - this should never be done.

Required tools and material

Before starting work, prepare the tool. To build a structure around the battery you will need:

In addition to the tool, you need the following material:

The material needs to be prepared in the right quantity so that you don’t have to go to the store to buy more.

Algorithm of actions when creating a box to hide the battery

There are two ways in which you can disguise a heating battery behind a plasterboard structure: cover the radiator with a decorative wall made of plasterboard or build a regular plasterboard box around the radiator.

Which method should I use? It all depends on the layout of the apartment and the location of heating communications in the room.

The construction of a box is advisable if the radiator is located on the wall. You can do this with your own hands from plasterboard quite quickly. This method is more preferable, since only the battery is masked, and the usable area does not suffer.

The dimensions of the box will depend on the battery that needs to be hidden. It is important to consider that the edges of the box will be approximately 15 cm further from the battery, on all sides.

Whether the box will be floating or standing on the floor depends on the interior of the apartment and the designer’s decision. Once a decision has been made on the design of the box, surface preparation and marking should begin.

Step-by-step installation instructions

Preparing the base

To build a structure, the foundation must be properly prepared. The old coating is cleaned from the surface, dirt and dust are removed, and primed.

If the wall on which the battery is located has significant unevenness, then it should be made smooth using gypsum plaster. Then it is advisable to putty the surface, since it will be impossible to do this after the construction of the structure.

Markings and drawings

If you plan to make a floating box to disguise the battery, then:

If a box standing on the floor is installed, the markings begin from the top edge of the battery, and perpendicular lines are drawn from top to bottom. You can see how to do this in the photo.

In addition, the box is marked on the floor so that the end of the box on the front side protrudes 15 cm relative to the radiator.

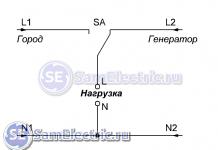

Example of a screen frame drawing

Example of a screen frame drawing

In some apartments, heating radiators are installed in niches that developers provide under the windows. In this situation, only the second method of constructing a box is suitable.

Some apartment owners want to radically change the interior of their apartment. In this case, it is possible to construct a false wall made of plasterboard, which hides all heating communications, but it is worth noting that this method is more financially expensive.

Frame assembly

The first thing you need to do in order to cover the battery with plasterboard is to mount the frame. To do this, you need to take metal profiles, galvanized 60x28 and 27x28.

First, the elements that will be on the wall are fixed. The algorithm is like this:

After this, the second level of the frame is installed. Cut the profile into pieces to the required length. Cut the edges of the elements by 5 cm, along the fold of the profile.

Box frame

Box frame

The edges of the profile are cut off, and the middle cut part is bent to the side, securing the sections at an angle of 90 degrees to the wall profiles

In the case of constructing a structure along the height of the entire wall, the profile pitch will be 60 cm.

The next step is to attach the vertical pieces to the front of the structure. Once the frame is ready, you can begin covering it.

Important! The frame, made of a profile to disguise the heating radiator, must be strong and rigid.

Attaching drywall to the frame

Cut the gypsum board into pieces of the required size. Fasten them to the frame using black self-tapping screws, 15 cm apart.

The screws are screwed in very carefully, using a screwdriver at low speed. Make sure that the head of the fastener does not fall into the drywall and damage the material.

It is worth noting that working with the material is quite simple. You can install a corner false fireplace made of plasterboard, which will heat the room.

Installing Thermal Hole

As soon as the plasterboard box for the battery is constructed, there remains a “window” in it from which the battery will be visible; it is covered with a decorative screen, which will help the warm air to be evenly distributed throughout the room.

Finishing of the finished structure

Rough finishing of the box is carried out using the following technology:

- seams between pieces of material are sealed with sickle and putty;

- putty is applied to the screw heads;

- as soon as the seams are dry, the entire surface is puttied in two layers;

- After the structure has dried, it should be sanded.

At this point, the rough finishing of the plasterboard structure that covers the battery is ready.

Design options

The box, which serves to disguise the heating radiator, can be decorated with any material: painted, wallpapered, decorated with decorative plaster. The cladding will depend on the overall interior of the apartment and the preferences of the owner of the room.

Cover the heating radiator with plasterboard with your own hands: photo

How to hide the battery and pipes with plasterboard with your own hands. Stages of installation work with step-by-step instructions and photos.

Arriving home again and looking around the room, my eyes stopped at the ugly cast-iron ribs of the radiator, which had already peeled off and instead of white had acquired a dirty gray tint.

I decided not to put off this problem for long and began to think about how to do it.

Someone might think that making radiator screens yourself is an extra hassle. After all, you can buy a decorative screensaver and thus solve the problem. But ready-made products are not always suitable for your battery. I had two metal screens hanging at home for a long time, and still one stuck out to the side, since the size was not quite suitable for the radiators.

Making screens for batteries is not such a difficult matter; the design is quite simple. You can install it yourself, it will be inexpensive. The most suitable material is drywall. It is easy to use and easy to cut and cut. In addition, all the necessary connecting elements are available for sale at any hardware store. You also don’t need complex construction tools; you usually have them in the house.

Preparation of material

Since drywall is still a material that is susceptible to drying out under the influence of temperature, it must first be prepared.

Preparation will consist of treating the drywall with PVA glue on both sides. This will secure the material and prevent it from cracking and drying out.

It would be better to paint such a prepared surface or glue wallpaper on it.

Frame formation

Finishing

After the box is assembled, all seams are sealed, the corners are strengthened using corners, mesh and putty. Putty is applied, then the corner is attached, the mesh is attached, then putty again. After drying, the surface is rubbed with sandpaper. The final step will be painting or wallpapering your screen.

In some apartments, it may be more expedient not to install a screen, but to completely cover the heating radiator along with the pipes with a plasterboard false wall.

Look at the video how to install such a false wall

You don’t have to do it yourself. Installing a screen on a battery can also be done to order, and it can only be yours.

Perhaps a purchased screen will not fit well into your interior, but a plasterboard screen will form a single whole.

Making a plasterboard box for a heating radiator, the advantages of the selected material, the preparatory stage, marking the location of the structure, making its frame, covering with plasterboard and finishing the product.

The content of the article:

The battery box is an excellent solution for disguising the heating device. This is especially true if the appearance of the radiator leaves much to be desired and disrupts the harmony of the interior. A home-made battery box can be adapted to match the color of the furniture, simply painted, covered with wallpaper, decorated with decorative stone or tiles. Today we will tell you how to make it using plasterboard sheets and metal profiles.

Advantages of a plasterboard box

In order to beautifully design heating radiators, today there are a lot of different options. Wall-mounted screens with and without lids, flat screens and attached boxes are widely used. Finishing of heating devices is made with metal, glass, plastic, wood, MDF and gypsum board. However, many people prefer to use drywall, since in this case it is easy to cover the radiators yourself.

In addition, the material is excellent for work due to its unique properties:

- It is environmentally friendly and therefore safe for long-term use.

- It has excellent physical and mechanical characteristics, which allow it to be used both in living rooms and in wet areas with appropriate processing.

- Installation of gypsum boards is quite simple; any home craftsman can handle it.

- The material is quite affordable.

- The battery box made of plasterboard can be easily dismantled if necessary.

- Radiator casing allows access to their valves and other shut-off valves.

- A plasterboard box can have different configurations due to the ability of the material to take any shape.

- Condensation never accumulates on the surface of the gypsum board.

- The design of the box can include functional shelves and niches that will allow it to fit well into any interior.

Preparatory work before installing the gypsum plasterboard box

Before making a box for the battery, it should be cleaned of old paint and repainted, since after installing the structure this will not be possible. The enamel will protect the radiator from corrosion and extend its service life. The box will take up a little more space than the heating device itself. Under the window sill, the structure can be placed either mounted on the floor or in a hanging position like a wall cabinet.

To construct the box, you will need measuring and working tools: a hammer drill and a drill with a diameter of 6 mm, metal scissors and a screwdriver, a construction level, a pencil and tape measure, a stationery knife, a stapler and a grouting mesh.

The materials you will need are: wall plasterboard, perforated corner, galvanized profiles UW 27x28 and CW 60x27, sickle tape, screws for fastening frame elements and its cladding, dowel-nails 6x40 mm and gypsum putty.

Further work will include several stages: applying markings for installing the box, manufacturing its metal frame, covering the structure with plasterboard sheets, puttingty on its surface and installing a thermal grill into the finished product.

Marking for plasterboard box for battery

Before applying markings, you should pay attention to the location of the window sill console in relation to the outer plane of the heating radiator. It should hang over the battery by at least 30 mm. If this is not the case and the window sill is too narrow, it should be replaced with a wider one.

To do this, you need to dismantle the old board, cut out a new window sill with the appropriate dimensions and install it at the base of the window frame. In this case, the window sill must be in a strictly horizontal position, which can be checked with a building level. The cavity between the board and the base should be filled with foam. After it hardens, you can continue working on the box.

Its future dimensions depend on the size of the heating radiator. In any case, the distance from the side surfaces of the device to the walls of the box must be at least 100 mm. It is also the smallest to allow installation on the front of the removable screen structure.

Marking the box for the heating radiator should be done in this order:

- First you need to determine the position of its bottom. If it rises slightly above the floor, then at this level you should draw a horizontal line along the wall and check it with a building level. If the box is connected to the floor, then three lines need to be applied to the coating: two of them are lateral and will indicate the depth of the structure, and the third, connecting the ends of the previous lines, will be the boundary of the front part of the metal frame.

- After this, the inner ends of the side marking lines need to be projected onto the wall using a square and brought to the desired height to the base of the window sill. The verticality of the two lines obtained should be checked with a level. Then their upper ends must be connected with a horizontal segment.

Making a frame for a battery box from gypsum plasterboard

Installation of the frame should begin with the installation of guide profiles UW 27x28. They should be located along the marking lines marked on the wall, floor and under the window sill. In order to create the depth of the box, UW 27x28 profiles should be attached to adjacent surfaces with the open parts facing out.

The installation process looks like this:

- The guide profile must be attached to the marking line and through it, using a small drill using a drill or screwdriver, mark several fastening points on the wall. After this, the profile should be removed.

- Then, according to the marks, you should drill holes for the plastic dowels, using a hammer drill and a drill with a diameter of 6 mm.

- It is necessary to insert dowels into the resulting holes, attach the guide profile to the line with both shelves outward until the holes coincide and secure it with self-tapping screws using a screwdriver.

- The fastening spacing should be 150-200 mm; it is better to fix the edges of the profile first, and then its middle part.

- In a similar way, you need to fix the UW 27x28 mm profiles on the floor and under the window. To install the profile under the window sill, use screws no longer than the thickness of the board.

- When installing guides between the base and the outer part of the profiles, it is necessary to lay a shock-absorbing tape that will dampen vibrations of the structure and maintain its secure fastening to the screws.

- CW 60x27 profiles should be cut into pieces of the required length.

- In the folds on both edges, it is necessary to make cuts of 4-5 cm.

- Then the middle of the profile needs to be bent down and its sides cut to the width of the shelf.

- After this, the channel sections should be connected at right angles to the edges of the vertical guides. The ends of the segments should face the inside of the room.

Sheathing the frame of the battery box with plasterboard sheets

The process of installing gypsum boards on the frame of the box is absolutely not complicated. It is performed in the following sequence:

- A sheet of drywall must be applied one by one to the sides of the frame, tracing them with a pencil and marking the places where it will be cut on the gypsum board.

- After this, the sheet must be cut into pieces of appropriate shapes and sizes. It is convenient to do this with an ordinary stationery knife, using a metal ruler.

- The finished parts should be secured with screws to those parts of the frame for which they were cut from the sheet. GKL fastening should be done in increments of 100-150 mm.

- In order not to get confused with the design of the corners of the box, it is recommended to immediately install each cut out part in its place.

- In the front part of the box you need to provide space for a heat shield. Its standard sizes are 600x600, 600x900, 600x1200 mm. The hole in the wall for it should be slightly smaller. The screen is inserted into the box after its finishing is completed.

Features of finishing a plasterboard box for a battery

After completing the assembly of the battery box, you can begin finishing it. First, you need to slightly cut the seams between the plasterboard sheets, prime them and then putty them using reinforcing sickle tape.

After this, the outer corners of the box must be reinforced with a perforated metal corner. Its installation is carried out using gypsum putty and makes it possible to give the corners of the structure a beautiful and regular shape. The recesses on the surface of the box left by the heads of the screws should also be filled with putty.

When the composition has dried, the locations of the corners, recesses from fasteners and gypsum board joints should be sanded with an abrasive fine mesh and then cleaned of gypsum dust.

After this, the entire box must be primed to ensure adhesion of the base with the finishing material chosen for the design of the product. The resulting surface is quite suitable for wallpapering or tiling.

If the box is planned to be painted, then before doing this it should be completely covered with a layer of starting and then finishing fine-grained putty. After it has dried, the surface of the structure must be brought to a perfectly smooth state by sanding, then primed again and painted with enamel in 2-3 layers.

After finishing the finishing, you need to install a decorative screen in the box. To fix this grille, you can use various latches or secure it using a targeted application of liquid nails, calculating it so that the screen does not fall off spontaneously, but if necessary, it would be easy to remove.

How to make a battery box from plasterboard - watch the video:

When assembling the box and finishing it, it is important to take into account that it not only masks the heating radiator, but also serves as a full-fledged element of the interior. Therefore, the design of this detail must match the style of the room. Good luck!