Job source: Decision 4951.-17. OGE 2016 Mathematics, I.V. Yashchenko. 36 options.

Task 16. To prepare minced meat, we took beef and pork in a ratio of 11:39. What percentage of minced meat is pork?

Solution.

The ratio of 11:39 in minced meat means 11 parts of beef and 39 parts of pork, and the whole part is equal to 11 + 39 = 50. Let's take the entire part as 100%, and 39 parts of pork as x%, then we can write the ratio:

where we find x:

![]() .

.

Answer: 78.

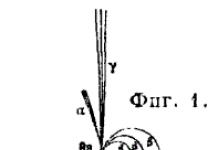

Task 17. The picture shows a well with a “crane”. The short arm is 1 m long, and the long arm is 4 m. How many meters will the end of the long arm drop when the end of the short arm rises 0.5 m?

Solution.

The problem comes down to the similarity of two right triangles. The first triangle is formed by a short arm of 1 m (hypotenuse, see figure), and the second by a long arm of 4 m. The heights from the edges of these arms to the ground form right angles with the surface of the earth. And the whole pole (“crane”) forms two vertical angle(equal) with the surface of the earth. Thus, the triangles are similar at two angles.

For similar triangles, we can write the following ratio of their sides.

The story of the first crane well begins during the New Kingdom in Egypt (1550-1069 BC). The most ancient form of such a well was called shaduf and it was also used for irrigating the land. But the operating principle of this structure has remained unchanged to this day.

Lowering the bucket and raising the water is carried out by a lever with a counterweight at the other end.

They tried to install the first wells next to a tree, using it as a support for a balance beam.

The design of the crane well consists of the following parts:

- balancer (otherwise called boom, rocker arm);

- boom stand (support);

- pole;

- chains;

- bucket;

- cargo;

- counterweight support (optional);

- well.

The advantage of the “crane” is that it is much easier and faster for them to raise water than on a well with a collar. But unfortunately, it can be used on wells with shallow depth, otherwise the design will become too bulky.

Because of this drawback, such wells are generally no longer built, if only as decoration.

Before starting construction, it is necessary to make all the calculations for installing a crane well.

- Determine the location for constructing the well and installing the rocker arm.

- The well should be located away from sources of pollution (25-30 m).

- The distance from the main building must be at least 10 m.

- It is best to install the well in an elevated place.

Building a well

The well consists of three parts:

- cap (will protect the well from debris and prevent it from freezing);

- mine;

- water intake part.

The mine is dug in the place where the groundwater is closest to the surface of the earth (it is better to invite a specialist to find the optimal location). Burial depth in aquifer usually does not exceed 1 m.

Advice ! Dig the well shaft in the fall or summer during the dry season, as this is when the groundwater level will be at its lowest.

The hole can be dug completely at once or gradually.

The frame for the well shaft is made of wood, brick, stone, concrete. The main thing is that it should not allow the soil to crumble into the well and prevent groundwater undrinkable from entering from upper layers soil.

The shape can be either round or square, or multi-faceted.

Important ! The depth of the shaft and methods of strengthening largely depend on the type of soil.

Well made of concrete rings

The diameter of the hole should be 20 cm larger than the diameter of the rings, for more convenient lowering, and also to fill them with gravel or sand from the outside.

If the hole has already been completely dug and the water has been pumped out, they begin to lower the rings one by one, securely fastening them with a lock or special staples. The last ring should rise above the ground by at least 20-30 cm.

If you decide to dig a hole gradually, then first a recess the size of one concrete ring is dug, but so that it protrudes slightly outward (20-30 cm). After it is lowered, the hole is dug further, but without leaving internal space rings. As soon as the height of the depression becomes equal to the height of the next ring, they begin to remove the earth from under the edge of the first one so that it begins to settle and sink deeper. The second ring is installed and so on.

Wood well

The most common material for building a well is wood. The wood used is oak, alder, aspen, pine, larch, birch, linden, and willow. It is better to take stained oak, then it will not give the water a bitter taste and color, and will also last 20 years longer than untreated.

The wood should be dry, free of rot, mold and dust, and also carefully inspect for the presence of bark beetles. Bark and knots are removed from the logs, but upper layer must remain intact.

The diameter of the logs is at least 180-200 mm.

Attention ! Under no circumstances should wood for a well be treated with chemicals.

You can start building a wooden well when it is already completely finished pit or by gradual immersion method.

In the first case, the first crown is installed on the bottom, and then the next one is fixed, and so on.

In the second case, a hole 1-1.5 m deep is dug and three crowns are installed at once. Then the depth of the shaft is increased by 25 cm and the earth is removed from the middle of each side of the crown. They install supports and remove the earth from the corners, and after that they are knocked out and the frame begins to settle.

The bottom of the well is first covered with a layer of coarse sand, and then a layer of gravel is poured (for better water filtration).

Surface of all wooden parts must be cleaned so that there are no splinters.

After completing the construction of the well, it is necessary to constantly pump water out of it for several weeks so that the entire structure is completely cleaned. The pumped water can be used for technical purposes.

Safety during well construction

Digging a hole for a well is a very dangerous job. Under no circumstances should you do it alone. At least one person should always be nearby.

For insurance, a rope must be tied to someone who is at the depth of the well, in case the ground collapses.

Helmets must be worn on the head.

From time to time it is necessary to rise from the mine, and also check the amount of oxygen in it (if the candle burns, then there is enough of it there). If dizziness or nausea occurs, you should immediately leave the well.

When digging a hole reaches the aquifer, you should start pumping out the water with sediment or scooping it out with a bucket so that the soil does not collapse.

Crane installation

First of all, you need to determine the dimensions of the “crane” for the well. And this directly depends on the depth of the mine.

It is very important to correctly determine the length of the short and long arms of the crane well.

The table below shows the dimensions of the “crane” taking into account the depth of the well.

Well depth h, m | Height along axis B, m | Distance h 1, m | Long arm L, m | Short arm L 1, m | Counterweight mass m, kg |

That is, if the well is 7 m deep, then the short arm should have a length of 3 m.

The picture shows the complete structure of a crane well.

- 1 - crossbar for support (dig into the ground about a meter);

- 2 - support (stand);

- 3 - load (counterweight);

- 4 - balancer;

- 5 - ring with chain;

- 6 - pole (the length of the pole is equal to the depth of the well);

- 7 - chain with fastening for a bucket.

First you need to install the support. It can be made from timber (50×100 mm). To ensure that the beam is exposed to moisture as little as possible, it is recommended to install it using two steel channels concreted 80-100 cm into the ground. In this case, the distance ( free space) from the beam to the ground after installation must be at least 20 cm.

The boom is attached to the post with a hinge unit (two steel angles and an M10 pin). The corners are secured to the support with M8 studs.

A pole is attached to the arrow with a chain, and a chain with a bucket is attached to the other free end of the pole.

Advice ! Attach a weight to the top of the bucket, then during the dive it will turn over on one side and sink.

A weight is placed on the short arm of the boom (you can also secure it with M8 studs).

To prevent them from falling into the well precipitation and garbage, you should either make a wooden lid or install special doors.

You can make a crane well with your own hands, the main thing is to follow the calculations and observe safety precautions, especially when working with the pit.

Well design

There are many options for how to design a crane well at your dacha. They all depend entirely on your imagination and capabilities. So, for example, an arrow can be made in the shape of a bird (crane, heron) or any other character.

Around the “crane” you can sprinkle everything with gravel and place flowerpots with flowers.

If the well is made of concrete rings, then you can paint it in one color or several, and also draw an unusual design.

And for decorative well-crane more more options design. You can plant flowers completely around it, even climbing ones, or install many pots of flowers.

A crane well can not only provide water, but also make an interesting addition to the design of the yard, decorating it, and is always pleasant to touch.

crane

■ You won’t often see a well crane at a dacha or garden plot. It seems like a simple thing, but those who like to grow vegetables and fruits don’t want to mess with it. Difficult, they say, very difficult. Unusual... And will it be convenient to get water with it? So I decided to help everyone who is interested in understanding the well crane and give proven personal experience and calculations advice on the construction of a crane.

But first, about the advantages of a crane over another water-lifting device - a gate. First of all, let’s say that less time and effort is spent scooping and lifting a bucket of water with a crane than with a gate. If you need to pour water into a barrel, then the crane is absolutely indispensable: you can’t lift the bucket to the height of the barrel with a collar; you still need to “press” it with your hands. At the same time, the construction of the gate requires scarce forgings and chain. So the advantage of the crane here is obvious. Now let's move on to the construction of the crane (fig.).

So, we build a crane near a well with a depth H, say, 4 m from the surface of the earth and with a neck with a diameter of 0.7 m. This neck diameter is standard, it allows you to install a ladder into the well and allow a person to go down there. Now for our well we need to determine the length of the pole, the length of the front arm and the entire rocker arm, the height of the stand and its installation location, and the weight of the counterweight.

Let's try to simulate the work of a crane. So we scooped up the water, raised the bucket and poured the water into the barrel. Let's calculate the stroke length of the pole L. The lower end of the pole in the lower position usually does not reach the bottom of the well by 0.3 m, since it is not recommended to scoop water from the well to the bottom. To the top

In this position, the lower end of the pole should be at a height of 1.5 m, then between the suspended bucket (0.4 m) and the barrel (1 m) there remains a gap of 0.1 m. Thus, the stroke of the pole L = H - 0.3 m + 1.5 m. That is, in our case L = 4 -0.3 + 1.5 = 5.2 m. Based on practice, we will take the length of the pole to be 0.3 m greater than its stroke, so that the end of the rocker arm in the lower position does not threatened with head injury. So, the length of the pole is 1.5 m greater than the depth of the well.

Actually, the concept of “pole length” here is quite arbitrary, since top part This length (about 1 m), necessary for maneuvering the pole, is made of rope, cable, belt or chain, and only the remaining part is made of a thin pole or beam. Consequently, the length of the pole (beam) itself is not H + 1.5 m, as indicated above, but will be less by the length of the flexible suspension! That is, the length of the pole itself is thus H + 1.5m-1m = 4.5 m.

The end of the rocker with a pole during operation describes an arc, and the chord that corresponds to this arc is equal to the stroke length of the pole L. It is also clear that the height of the chord is equal to the diameter of the well neck. The radius of this arc R, which is nothing more than the length of the front arm of the rocker arm, can be easily calculated using the formula:

where L is the stroke of the pole, m;

d - diameter of the neck, m. Due to the maneuverability of the pole (the ability to deflect the bucket from the walls of the well), the diameter of the neck can be taken equal to 1 m in calculations, that is, “increase” by 0.3 m. Mathematical calculations (they are not

The crane well is not just original and beautiful, these words reek of something deeply folk, romantic, vital and forgotten. Nowadays, such wells are very rare, although not so long ago - only 30-40 years ago - such structures could be admired much more often.

Wooden wells: a - cutting knife; b - laying supporting logs under the frame; c - bell (tent); 1 - stone; 2 - wedge; 3 - log.

Lifting a load using a counterweight and balancer is probably the most ancient, reliable and simplest method. It is quite easy to install the support and attach a suitable balance pole to it. A counterweight is installed on one side of this pole, and the load itself is suspended on the other, which can be lifted quickly and without much effort.

Crane well: main features of the device

The crane consists of a base for which a strong vertical stand. A balance beam is attached to it using hinges. A pipe, pole, or thin log can be used as a balancer.

A pole is attached to the long part of the balancer, the length of which should correspond to the depth of the well. You need to tie a bucket to the pole. The short part of the balancer is crowned with a weight, which can be firmly fixed, or can move along the balancer, reducing or increasing the weight of the counterweight.

When building a well with their own hands, our ancestors tried to make it not far from a tree, the trunk of which later served as a support. If nothing grew nearby, then suitable tree they tried to find it in the forest, and then dug it in near the well. A hole was made in the pole into which the axle was inserted. Using an axle, the pole was secured in the fork of a tree.

Currently, to create a crane well with your own hands, more familiar methods are used. modern man materials. The base is solid wooden beam, channel, metal pipe.

Scheme of raising water from a well: a - using a gate; b - with the help of a crane; 1 - gate; 2 - rope or chain; 3 - preponderance of the crane; 4 - counterweight; 5 - crane woman (post with a fork).

Using metal plates, hinges and corners, a balancer is attached, which, like a pole, can be made of any suitable material.

Prepare tools and materials:

- threaded rods;

- nuts;

- bearings;

- hook;

- cable;

- electric jigsaw;

- board;

- metal chain;

- wooden beam;

- screws;

- self-tapping screws;

- bucket;

- screwdriver;

- self-tapping screws;

- pipes and bars for the crane.

Raising water with the help of "Cranes".

The standard crane has the following dimensions:

- length of stepsons - 2 tubes 5 m long;

- stand height - 2.7 m;

- pole - 2.2 m;

- boom - 3.1 m;

- chains: lower - 0.5 m, upper - 1 m;

- bucket - 9 l;

- counterweight - 18 kg;

- hand drill or shovel;

- wrench;

- sandpaper;

- watering can for watering plants.

Return to contents

Digging a well for a crane

The well consists of several main parts: the top (head), the middle and the longest - the main trunk, in which water will accumulate. The head is designed to perform 2 tasks. First of all, it protects the water from dust, dirt, snow and grass. It also prevents the well from freezing in winter.

The most optimal shape for the main trunk of a well is round, but rectangular, square and hexagonal can also be made. Water is collected and stored in a reservoir, the depth of which depends on the volume of liquid consumed during the day. Optimal depth water is considered to be 1 m. If you are building a well in an area with low-water soil, the water intake area must be placed at the maximum possible depth.

Select a place to build a well in advance. Source drinking water must be located at a distance of at least 30 m from manure heaps, toilets, etc. Choose an elevated location for the well - this will reduce the risk of water contamination. The distance between the well and country house must be at least 3 m.

First of all, it is necessary to dig and strengthen the shaft. The depth of the shaft and the procedure for strengthening it depend on the soil on the site. It is better if there is solid soil in the area where you are digging a well hole. Using an excavator or any other suitable equipment, dig the required recess.

After the shaft is ready, you need to level the bottom of the well and pump out excess water. The first frame is installed from the thickest and strongest logs. If the soil is weak, large stones should be placed under the first frame.

Next you need to install the crown. It is installed strictly vertically. This can be checked using a level. A second one is placed on top of the crown. For better fastening, the upper part must be compressed with blows of a special wooden hammer.

Clay is used to seal the seams between the crowns. The bottom of the well is covered with a layer of sand and gravel. To avoid distortion of the frame, with inside In the corners you need to nail strong boards. For low-water soil, the log house should be in the form of a tent. On this underground part The crane's well is ready. The next step is to create the above-ground part of the structure, which can be made of wood or stone.

Return to contents

Design of the above-ground part of the well: step-by-step instructions

Concrete wells: a - reinforced concrete ring; b, c - a mold for the manufacture of simple concrete or reinforced concrete rings; g - reinforcement; d - reinforced concrete ring with a lock; 1 - boards; 2 - wooden ring; 3 - reinforced concrete (reinforcement is shown in dotted lines); 4 - boards.

Wood can be used as the main material for constructing the above-ground part of the well - it is very easy to process. The base of the structure is a box. It can be made in the form of a log house made of logs or timber, or covered with planed boards.

As the basis of the box, you can take 4 racks made of 100x100 mm timber, 1 m high. Screw the sheathing boards to the racks using screws. To make the base of the structure more reliable, the corners should be covered with platbands.

The design of the crane well does not imply the presence of a roof and a drum for raising the bucket, so this is where the construction of the above-ground part of the structure ends. Then you can go directly to the crane device.

Return to contents

Crane diagram for a well: AB - shoulder lifting a bucket of water; b - mass of a bucket of water; BC - counterweight arm; C-load.

The well-crane type water lift has its advantages and certain disadvantages. It is precisely because of the existing shortcomings that such a system has been relegated to the background in modern well construction.

A well from which you can easily get water using a crane should not be too deep (optimally up to 3-5 m). Otherwise, the structure will turn out to be too high, which will negatively affect its strength and will take up too much space.

The most a big problem- this is closing such a well. As a rule, in such designs either the lid is completely absent, or it is simply placed on top of the head, which does not allow achieving the necessary tightness.

There are many options available for constructing a crane well. It all depends on the design of your yard or plot, imagination, location of the well and its depth, features of the arrangement of the well head and other factors. It is necessary to consider the basic principles of constructing such a well with your own hands and one of the main methods of using it.

First of all, the support is installed. In this case, its functions will be performed by timber. The length of the beam should be 2.7 m, the cross-section should be 50x100 mm. A thicker beam, of course, would be more durable, but installing it would require more effort. In order to avoid rotting of the timber, it must be isolated from contact with the ground. For this reason, 2 steel pipes must be used as a support base.

The distance between the well head and the support is determined, after which a hole with a depth of at least 1 m is drilled or dug in the right place.

The pipes are screwed to the support using mounting pins with the expectation that after lowering into the hole there will be a distance of about 17-20 cm between the soil and the support.

The pipes must be driven into the hole and concreted. The support is fixed with supports and remains for 3-4 weeks (until the concrete gains strength).

Next, the boom is installed on the support. It is made from 50x50 timber. At the point where the support and the boom are attached, the latter must be reinforced using an overlay made of the same timber. The boom is mounted to the support using a hinge unit. It is made from a mounting stud and 2 steel angles. The corners are attached to the rack with 4 mounting studs.

The pole is made from a duralumin tube, which it is advisable to cover with a modern moisture-resistant wood-like film. The pole is hung on the arrow. It is attached using a galvanized chain 100 cm long. After that, a bucket is attached to the pole with a galvanized chain 50 cm long, to the top of which a load is attached, so that immediately after contact with water the bucket will turn over and sink.

After that on reverse side a counterweight is mounted on the boom. For this, 2 metal bars with a total weight of 18 kg are suitable. The bars are attached to the boom using the same mounting studs. At this point the crane well is almost ready. The last stage remains, namely, decorating the well support.

Usage ancient way raising water to the surface using a lever and a counterweight and today is often used in the form of traditional wells, where a rocker with a weight at one end and a pole with a chain at the other is mounted on a high support. Such designs are gradually becoming a thing of the past, because the tradition of having a crane well in a farmstead is being actively replaced by more advanced technologies - wells, or a central water supply. Although, as practice shows, it is precisely this kind of original well that attracts many to build in their yard

Design Features

The idea of using a balancer for installation next to a well is reflected in the culture of many nations, and now similar designs are found not only in Europe, but also in Asia and Africa. The simplicity of the design makes it possible to significantly facilitate the process of raising water and use such a well even for systematic watering of the land. Of course the rise small amount water with a capacity of 10-12 liters from a depth of 3-6 meters using a lever with a counterweight does not have great productivity, but on the other hand, this is the easiest way to get water from a source with a minimum amount of effort.

The simplicity of the design makes it possible to use improvised means or even existing trees as support, but otherwise the well consists of the following parts:

- Rocker;

- Pole;

- Additional chain or cable;

- Balancer weight;

- Support for balancer;

- Equipped well.

Alas, for most areas where the aquifer lies at a depth of more than 8 meters, such a structure will be practically useless, unless the height of the support is about 8 meters, and the width of the well frame is at least 3 meters. But for other areas where the aquifer lies at a depth of 3-6 meters, this option for equipping a well is quite realistic.

But still, before you start building the structure, you should carry out preliminary calculations and make a plan construction work, after all, the equipment of such a well requires large area to place all the elements.

Calculation of the main parts of the well

When constructing such a structure, the most important point the correct calculation of the lifting lever is important, because incorrect calculations will require best case scenario a simple alteration of all elements, and at worst they will remain a decorative attribute of the estate.

The first indicator necessary for calculations is the depth of the well to the bottom where the pebble layer is located.

The second calculated indicator is the calculated linear dimensions of the lever - too large a lever requires not only a higher support, but also the need for a wider neck of the well itself. It should be taken into account that despite the large lever, the counterweight load, even for such a weight as a 10-liter galvanized bucket, will require at least 30 kg.

An example would be the calculation of a well 10 meters deep. For such a well it is necessary to raise the rocker axis to a height of 5.8-5.6 meters. The length of the rocker itself is also 10 meters, as is the depth to the bottom; the long arm of the lever will be about 7.5 meters, and the short one with a counterweight of 30 kg will be no less than 2.5 meters.

To build a well you will need concrete rings with a diameter of 1.2 meters, a height of 1 meter - 11 pieces. This quantity is necessary for installation to a depth of 10 meters and installation of the head.

The site for the construction of the well is taken to be 10*10 meters in size, this is enough to initially place everything necessary materials and tools, and then equip a place to install a support with a lever.

Calculation of burial depth groundwater is carried out by studying the depths of nearby sources - within a radius of 100 meters around the site, it is recommended to measure the depth of all wells to determine average value depth of the aquifer.

Decorating a well to make it beautiful appearance should be postponed for more late date, since the main task is to find water and construct the mine itself, which is a much more important task compared to decoration. However, even at the calculation stage, it is possible to determine how the head will be designed, how much materials are needed to construct the log house, and how the lever, support and cover of the well will be designed.

Well construction

When starting work on excavating a shaft for a well, it is necessary, first of all, to take care of safety precautions - digging a pit of such depth must be carried out in compliance with safety regulations, one of which must be the presence of a safety rope and at least two people on the surface of the earth for emergency lifting of a person from depths.

To begin with, the site is cleaned, the first ring with perforated walls is installed in place of the passage. Next, the shaft is gradually deepened so that the ring gradually settles into the shaft. After the ring has been lowered to its full height to ground level, a second ring is put on and secured in a concrete lock. Gradually going deeper, all the remaining rings are installed in this way. After installing all the rings, including the top one, all the water is pumped out of the well volume and the bottom is covered with pebbles.

Most favorable time The year for digging a well is mid-summer - early autumn before the onset of the rainy season. This is the most favorable period not only for digging a well, in terms of dry weather, but also for determining the lowest level of the aquifer.

After filling the well with water, its daily debit is determined and they begin to mark the site for installing the support. For a support post, a log or oak beam with a cross section of 250*250 mm is usually used. The required length of timber is treated with an antiseptic, and the part that will be buried in the ground is additionally tarred and treated bitumen mastic. It is important that as a support it is selected healthy tree free of rot and damage.

In the upper part of the support, a sample is made to a depth of 30-35 cm; the width of the sample should be 2-3 cm wider than the size of the rocker arm. After marking, the rocker itself is treated with sandpaper to remove splinters, then it is adjusted to the location with the support and a hole is drilled for the central axis. It is recommended to make the axis from of stainless steel with threaded ends for fixation.

Before installation, the entire structure is assembled and checked on the surface of the earth in a horizontal position. Next, a support is installed in the open pit and secured with additional supports. Using a ladder, a rocker arm is installed. The axle is lubricated for easy movement. A rope is temporarily attached to the long side of the rocker and operation is checked without a counterweight.

After installing the pole and chain on the beam, you need to install the counterweight. It is recommended to make the load a composite of several small weights, so that it is possible to regulate the smooth operation of the crane.

It is recommended to install a long chain at the end of the pole using clamps and bolts - this will make it possible to adjust the desired length of the segment. The fastening of the bucket can be made permanent, or you can provide a carabiner at the end of the chain section for removing the bucket.