Home smoking meat, sausage, lard, fish has always been troublesome due to the length of the procedure. In addition, it was necessary to constantly intervene in the process, adjust the temperature and humidity of the smoke, otherwise the products could turn out raw or too dry. Electric smokers have been successfully used in the food industry for a long time, making it possible to reduce smoking time by an order of magnitude. This principle has long been known, there are no special secrets here, so if you wish, you can build an electrostatic one at home.

How does an electrostatic smoker work?

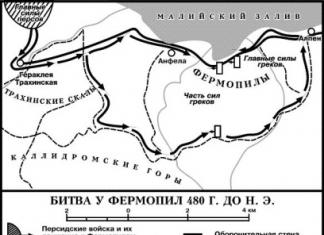

You can often come across the opinion that an electrostatic installation does not provide the same quality of processing of meat products that can be obtained using a classic smokehouse. In fact, both installations work exactly the same, with the only difference being that the electrostatic smokehouse has separate block, increasing the efficiency of smoke use. General principle Smoking is in many ways similar to steaming meat, only instead of hot steam, moist smoke from smoldering sawdust is used.

In a conventional smokehouse, only 1/10 of the smoke flow is used for processing, the rest settles on the walls of the chamber and is thrown away. In an electrostatic installation, due to the action of the electrostatic field, more than half of the flow is attracted to the surface of the food, which speeds up the cooking process significantly.

The design of the improved electrostatic smokehouse consists of five main components:

- Smoking box chamber assembled from wood or resistant plastic with high dielectric constant;

- A source of hot smoke, most often a steel container with a gas or electric heater;

- Cooler of the smoke flow to an operating temperature of 38 o C;

- A blower fan, with the help of which the flow is forced inside the smokehouse chamber;

- Electrostatic block.

The condenser or cooler, fan and chamber are connected to each other by non-metallic pipes, you can use two-inch polyethylene water pipe. The smoke generator and the condenser are connected to each other metal pipe. The best option would be a corrugated steel hose for connecting household gas stoves to centralized gas supply systems.

Advice! The less metal and electrically conductive objects there are in the design of an electrostatic smokehouse, the safer the installation will be. Use only plastic and wood whenever possible.

The voltage at the electrodes of the electrostatic system reaches 20 thousand volts. You can make an electric smokehouse with your own hands, in which the voltage will reach 25 thousand and even 35 thousand volts. This is a lot, for comparison, a person can feel an electric shock with a voltage of only 36V, so any potential leakage through the metal parts of an electrostatic smokehouse can result in a serious shock.

How does an electrostatic smoker work?

The operation of an electric smoking unit is practically no different from the operation of a conventional cold smoking chamber:

- Sawdust is loaded inside the smoke generator fruit trees, which are heated in a closed volume in the absence of air, during decomposition, hot smoke is released, saturated with water vapor and wood decomposition products - acids, aldehydes, alcohols and resins;

- In the cooling chamber, the smoke stream is cooled and cleaned of the most toxic part of the smoke - resins and tar. If this is not done, the electrodes of the electrostatic smokehouse will quickly become covered with a black, hard coating, and the effect electric field will disappear;

- The purified and cooled smoke is directed by a fan into the working chamber. Under the influence of a high-voltage electrostatic field, water, aldehydes and alcohols become charged and are attracted to the surface of meat products.

Advice! To produce smoke, use only fruit breeds wood, cherry or plum are considered the best. You cannot charge the smoke generator of the smokehouse coniferous species, walnut, birch, such wood emits a lot of tar and gives the products a terrible smell of burnt rubber.

Assembling an electrostatic smokehouse with your own hands

Today, two types of electric smokehouse designs are used in practice:

- With an electrostatic field generator on a line scanning unit from an old TV;

- On the ignition coil or magneto from a two-stroke engine.

There is no difference in the design of the smoking chamber body; only the design of the blocks with the help of which the electrostatic field is generated is different.

Assembling the smokehouse body

Chamber designs can be very diverse in shape and materials used. The best option There will be a smokehouse made from sheet fiberglass, textolite or getinax. All listed materials industrial production are highly resistant to water, smoke, chemicals and, most importantly, they have high dielectric impermeability. This means that with repeated use, the camera material will not become saturated with moisture and will not cause an electric shock if accidentally touched by hand.

The dimensions of the chamber depend on the power of the smoke generator and the system for generating an electrostatic field. For line scan units from Electron or Beryozka, you can make a smokehouse chamber measuring 30x30x50 cm. The older the TV, the more powerful block scans and electrostatic field, and the more you can choose the volume of the smokehouse chamber.

On inner surface side walls, two grid electrodes are installed from ordinary metal mesh with welded pieces of wire. These are anodes, or positive electrodes. electrostatic generator. The grids are secured with ordinary metal brackets, but the walls of the smokehouse cannot be pierced through. At the bottom of the smokehouse body is cut annular hole, to which the pipe from the smoke-injecting fan will be connected.

In the center of the smokehouse, a suspension is installed in the form of a metal hook and a ring with several needles. This is the cathode, or negative electrode of the electrostatic field. The products are hung from the hook, and the ring with needles is put on the place of suspension so that the points of the needles touch the surface of the meat.

Connect to the cathode and anode of the electrostatic smokehouse high voltage wires, it is best to use automotive armor wires to supply voltage to the spark plugs. The wires themselves must be marked so as not to be confused when connecting to an electrostatic field generator.

Manufacturing of smoke generator and cooler

The best housing for a smoke generator would be an old cast-iron roasting pan or a pressure cooker made of of stainless steel with a tight-fitting lid. Limestone or granite grits are poured into the bottom of the pan in a layer of 2-3 cm and placed electric heater. A nichrome spiral from an electric fireplace or iron, with strung ceramic insulator rings, is best suited.

A steel sheet is laid on top of the laid spiral with ceramics, with holes drilled along the contour, every 10-15mm, with a diameter of 3mm. Small chips are laid on the sheet, in a layer of up to 5 cm. A hole is drilled in the generator cover for installing a bronze half-inch fitting, to which a flexible corrugated hose of steel. The second end of the hose is directed to the smoke cooler.

To make a smoke cooling device you will need a small container and copper tube, with a diameter of 10 mm and a length of 150 cm. The tube is carefully rolled into a spiral with dimensions corresponding to the dimensions of the container. The manufactured coil is installed inside the container, a hose from the smoke generator and a cold smoke outlet leading to the fan are connected to the tube terminals.

Any centrifugal option operating on AC power can be used as a fan.

Electrostatic generator

Most often, a line switch from a TV is used as a device that generates an electrostatic field for a smokehouse, the diagram of which is shown below.

This is a small electrical board with connectors on which a high-voltage rectifier and transformer are installed.

If the board is in working condition, then to start it is enough to connect the anode and cathode of the electrostatic field, connect the power supply from the network, and you can start the smokehouse.

The second version of the electrostatic field generator works on induction coil mechanical system ignition In this case, the supply contacts of the coil are connected to a multivibrator, which produces current pulses with a frequency of 20-30 Hz, and from the ground and the central output, using armored wires, the electrostatic field is supplied to the cathode and anode of the smokehouse, respectively.

Most smokers need open fire for heating sawdust or a smoke generator. But there are smokehouses that do not need fire. The device is heated by electricity. If there is no desire or opportunity to purchase a branded device, then you can make an electric smokehouse with your own hands.

Combined electric smokehouse

These installations are convenient to use in a city apartment. They have advantages over conventional devices:

- installation on a balcony is possible;

- no need for a gas stove;

- heating the device using electricity allows you to automate the process by installing temperature sensors and time relays.

In factory-made home smokehouses, heating is carried out using tubular electric heaters. In DIY devices, in addition to heating elements, electric stoves are used.

Reference! heating element is heating device, having the shape of a straight or curved tube filled with insulating material. Along the axis of the tube there is a nichrome spiral. It is connected to the network and heats up when electric current passes through it.

Eat different variants location of heating elements:

- under the bottom of the smokehouse, while wood chips are poured onto the bottom of the smoking chamber;

- at the bottom of the chamber, and sawdust falls directly onto the heating element;

- at the bottom of the chamber, but a tray with sawdust is placed on the heating element.

In the latter case, if the dimensions of the device allow, it is possible to use a conventional electric stove as a heater.

An electric smokehouse for sausage is no different in design and principle of operation from an electric smokehouse for fish. In an electric smokehouse, regardless of its design, you can smoke any product; the temperature and processing time vary.

Before smoking, products must be salted or kept in a marinade, and sometimes boiled. After processing, smoked meats need to be left to mature for 30 minutes to several hours.

Hot smoked electric smokehouse

Most electric smokers are designed for hot smoking. They have smaller dimensions and consist of one block - a smoke generator and a smoking chamber. Usually they are combined in one building:

- there is a heating element at the bottom of the smoking chamber;

- sawdust is poured onto it, which emits smoke when heated;

- a tray for collecting fat is located at a distance of 5 cm from the sawdust;

- at a height of 10 cm from the pallet there are grates with products;

- the entire installation is covered by a front door or top cover.

These settings are higher than usual. To the size of the device installed on gas stove, the height of the heating element is added - 2-3 cm. When independent design hot smoked smokehouses, this must be taken into account in the drawing.

Reference! To turn a regular hot-smoked smokehouse into an electric one, you just need to place it on an electric stove.

The following diagram shows the main dimensions and internal organization electric smokehouses.

Converting a vertical smokehouse into an electric smokehouse

Vertical electric smokers have enough space to install an electric stove with a container for sawdust inside. The easiest way is to convert it to electrical device, made from a barrel with a capacity of 200 liters or make such a smokehouse from the refrigerator.

Step-by-step assembly instructions consist of the following points:

- at a height of 20 mm from the bottom, a Ø 10 mm hole is drilled for the wire;

- the plug is disconnected from the electric stove;

- the tile is placed on the bottom of the barrel, and the wire is passed through the hole;

- the plug is connected to the wire;

- A frying pan without a handle is placed on the electric stove, onto which sawdust will be poured.

Cold smoked electric smokehouse with smoke generator

Cold smoked smokehouses have a more complex structure. In these devices, smoke is produced separately, in a smoke generator, and enters the smoking chamber through the chimney. Passing through it, the smoke cools and enters the smokehouse.

Its structure is no different from conventional installations. This DIY smokehouse can be made from any smoking cabinet and an electric smoke generator.

It is a hermetically sealed cylinder with a capacity of 3 liters. At the bottom of the body there is a heating element, and in top part 2/3 of the volume is filled with sawdust and wood chips.

When heated, the wood chips release hot smoke, which enters the chimney and then into the smokehouse to the products. The temperature of the smoking process depends on the length of the chimney.

The power of such a device is 0.1-2 kW, and average consumption electricity 4 kWh per day. The greater the power of the heating element, the faster the heating occurs, but at the same time hotter smoke is released. Therefore it is advisable to smoking chamber install a thermostat that turns off the heating when the temperature is exceeded. There is enough smoke inside the chamber to keep smoking going.

A type of electric smoker is. Like other devices, you can make it yourself.

Interesting! In the first half of the 20th century, some cars had similar installations installed instead of a gasoline tank, only the wood chips were heated not by electricity, but by firewood.

Factory-made electric smokehouses

There are many companies that produce electric smokers. Among them are the electric smokehouses “Dymka” and “Solinger”.

Hot smoked electric smokehouse “Dymka”

Electric smoker "Dymka" Russian production made of food-grade stainless steel with a thickness of 0.8 mm and is capable of smoking 7 kg of food at a time. Inside the housing there are grates and trays for wood chips and fat. The lid is sealed with a water seal, and there is also a smoke exhaust pipe. This design ensures that there are no odors in the room.

The smokehouse has a built-in heating regulator and a thermometer mounted on the lid. This allows you to maintain the required temperature during the smoking process. The power of the heating element is 1 kW, which ensures heating of wood chips to 250-300°C.

Some models are equipped with an additional tank, which is installed instead of the lid. According to the manufacturer’s description, this allows you to smoke fish and sausage up to 80 cm long in a suspended state.

The installation has the following parameters:

- smoking chamber capacity 20 l;

- diameter 25 cm;

- height 41 cm;

- structure height 63 cm;

- weight without food and wood chips 7.8 kg.

Smokehouse "Solinger"

The Solinger smoking chamber is made of stainless steel. The tank capacity is 20 liters, which is enough for simultaneous smoking of 5-7 kg of products.

The smokehouse has a flat bottom, 2 mm thick, which ensures even heating and is suitable for use with stoves different types- gas, induction and conventional electric.

The lid is sealed using a water seal; it also contains a tube for connecting a smoke exhaust hose.

The electric cold smoked smokehouse is very popular due to its compact dimensions. It, unlike the traditional installation, allows you to smoke meat and fish not only on suburban area, but also in the house. You can prepare smoked delicacies both in a factory and in a homemade electric installation.

Both electrical appliances cope perfectly with the task of preparing smoked products. The difference is appearance and cost. Besides, homemade installations It is not recommended to place in apartments. For this purpose, it is better to purchase the factory version.

Factory and homemade electric smokehouses

Factory-produced electrical installations for cold smoking are more powerful than home-made ones. This is reflected in the speed of cooking, which is higher than in a home-made smokehouse. Such devices also differ in their more aesthetic appearance.

They are produced in rectangular and cylindrical shapes, and, instead of sawdust, they can work on special briquettes. The cost of the most simple models is about 2000 rubles, and more powerful and functional ones in the region of 10,000 rubles and above. Therefore, for real good installation for cold smoking it has a pretty decent price.

Homemade electric smokehouses are assembled from available materials, which makes the cost of installations minimal. This is the reason that many home craftsmen prefer such units to factory ones. It is enough to spend one day at work to always have cold smoked products on your table.

No special skills are required. You just need to have some materials and tools at your disposal, understand how the installation functions, and correctly carry out a certain sequence of work.

Operating principle of an electric cold smoker

Products located in the smoking chamber are treated with hot smoke. It is formed as a result of smoldering sawdust, wood chips or braces. The thermal effect of smoke causes the liquid from the meat products to evaporate, and the product acquires a bright taste and great aroma.

Cold smoking, unlike hot smoking, is carried out at a low smoke temperature of approximately 20-25 degrees. They reach meat products until ready from ten hours to several days. Fish smokes the fastest, and pork, on the contrary, takes longer.

The long cooking process is compensated high quality the resulting product. This is reflected in both taste characteristics and more long term storage, which is sometimes much higher than many store-bought smoked delicacies.

What materials are suitable for making an electric smoker?

The basis of the installation is the capacity. It must be made of heat-resistant material and have a volume that allows you to cook required amount fish or meat. You need to expect that smoking can take from ten hours to several days, and the chamber of the future smokehouse should be quite spacious.

A homemade smokehouse can be made from:

- 200 liter barrels;

- old refrigerator;

- steel sheet.

There is no preferred option. The choice is determined by the availability of a particular material. Not everyone has a refrigerator that has expired, and you have to work with steel sheets almost “from scratch,” but the advantage is that you can calculate the dimensions yourself. A barrel and a refrigerator are the best options.

Electric cold smoked smokehouse from a barrel

The container is made of durable and heat-resistant metal. Chemicals and explosives are stored in such barrels. If you don’t have one on your farm, you can purchase it. The cost will not be high. The main thing is that it has a lid.

Along with the barrel, you will need the following materials:

- Four wheels. This item is optional, but allows you to move the smoker with ease. Any furniture will do.

- Heating element and electrical cable. Without these components, the installation will not work from the mains.

- Thermostat. The best option There will be a device with adjustment ranging from 20 to 90 degrees, even if only cold smoking is intended.

- Thermometer. Without this device, using the smokehouse will not be absolutely safe; it will become impossible to control the smoking process.

The only tools you need are a metal drill, which makes creating an electric smokehouse as simple as possible.

Two pallets are required. One container will serve for fuel, the other to collect draining fat. The workpieces can be placed on a grid or a system of hooks. For convenience, both options can be combined.

Barrel preparation

The container is thoroughly washed. You especially need to carefully clean barrels that were not used for your own needs, but were purchased second-hand. Firewood or an armful of brushwood is placed inside and burned. This is done in order to get rid of any oily deposits and calcinate the walls.

When the wood is completely burned, the inner walls of the barrel are cleaned with a wire brush to remove any remaining carbon deposits. Next, the container must be rinsed with water and detergent added. household product.

As soon as the container is dry, install wheels and drill holes in the bottom for ventilation. In total, you need to make from 5 to 8 holes with a circle diameter of 10 millimeters.

Heating element placement

You can dismantle the old and no longer needed potbelly stove in the house. If you can’t remove the heating element yourself or you simply don’t have an old electric stove, you can purchase a heating element on the market or in a specialized store.

You need to take a heating element open type. It will be placed in the center of the barrel. It should be completely dry by now. The element is secured with bolts. IN close proximity a thermostat is located from it, connected in series copper wire with a cross section of 2.5 mm2. The device must be placed in a convenient place.

Arrangement of the upper part

Make a hole of small diameter through which the thermometer is attached. Place a tray or baking tray in the center of the barrel. This vessel is necessary to collect fat that drains from meat (fish) during cooking. A chimney hole with a diameter of 50 mm is made in the lid, which is equipped with a damper that is closed at the beginning of cold smoking.

The fuel pan can be made from a mesh pan or from an old regular saucepan. The volume of this container determines the smoldering time of sawdust (chips). A five-liter tray is enough for 10 hours of smoking at a temperature of 20 degrees. Therefore, when planning to cook pork, you need to either increase the volume of the container or make several additions of wood chips.

Testing the installation

If all the work was carried out correctly, you will end up with a smoking installation on the bottom of which there is an electric stove, and on top there is an area for placing workpieces. There must be ventilation, a tray for dripping grease, a container for sawdust, and a chimney hole in the top cover.

Once the assembly of the electric smokehouse is completed, it is not recommended to start smoking right away. First you need to lightly heat the barrel. The first warm-up should last from 10 to 20 minutes. After it, you can already add meat (fish).

Electric cold smoker from the refrigerator

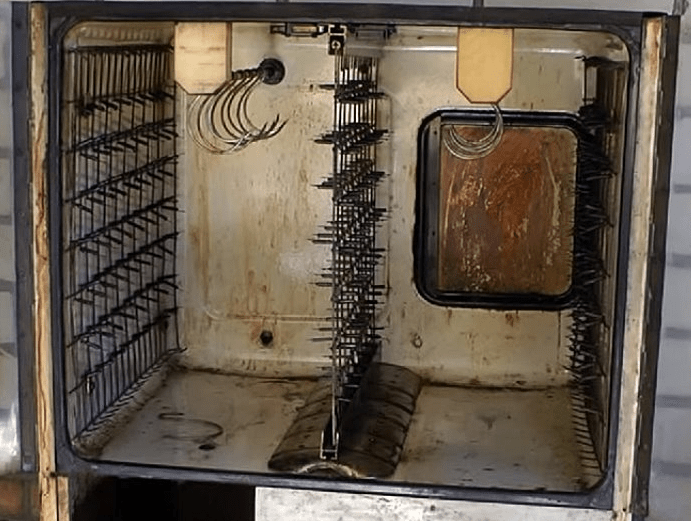

If old refrigerator failed, it will be an excellent basis for an electric smokehouse. The sequence of work when arranging such an installation is as follows:

- The cooling system and insulating elements are removed from the refrigerator.

- A heating element (heating element) or electric stove is installed at the bottom of the unit.

- The terminal block is led into a niche where the compressor used to be located. It is connected to the switch.

- A heat-resistant metal pan is placed directly above the heating element. The container for sawdust is placed on heating element or electric stove.

The convenience of this installation lies in the fact that the old grates that are in the refrigerator can be used to place meat and fish preparations.

You should not take a unit that is too large. Firstly, difficulties may arise with its location, and secondly, the efficiency will decrease.

The amount of fuel burned determines the duration of sawdust (chips) smoldering. Five kilograms, as in the case of a barrel, is enough to provide a smoking time of 10-12 hours.

Summarizing

An electric homemade smokehouse is perfect for installation in a country house or summer cottage. It is not recommended to place such an installation in the house. Some home craftsmen install such units on loggias and balconies, but this is not entirely safe. It is better to buy for an apartment factory model. It will be distinguished by its most compact size and excellent insulation.

High-quality smoking is impossible without the use of special equipment. Today on the market there are entire lines of smokehouses that operate according to different principles. In particular, models with smoke exposure, units with heat treatment etc. Each manufacturer’s family contains electric smokehouse, characterized by ease of use and the ability to use at home. However, there are also universal devices, the mobility of which allows you to process products both outdoors and indoors.

Main selection criteria

To begin with, the direction of the unit and the products that are planned to be smoked are determined. Majority modern models effectively serve fish, meat products, lard, sausage, etc. Next, the capacity of the products is determined. For example, an electric smokehouse entry level can provide simultaneous cooking of 2-3 kg. In more advanced versions, a load of up to 10-15 kg is expected. But it is important to consider that volume is directly related to compactness and mobility. That is, the massive structure will be difficult to take on a picnic.

The next important characteristic is the smoking time, which is determined by the power. The most productive models from the segment aimed at home use, have a power potential of 500-600 W. Again, depending on the loading volume, such an electric smokehouse can perform its function in either 2 minutes or 30 minutes - subject to maximum filling.

Hot or cold smoking?

Design parameters are usually oriented towards either one of the types of smoking or their combination. Hot processing involves thermal exposure of the product at a temperature of about 90 °C, and cold smoking is performed at 20-25 °C. In both cases, preparation time can vary from several hours to a week or more. However, an electric smoker can speed up this process. This cooking method is more difficult to implement technically, but the result is worth it. This design assumes the possibility of connecting the chimney to exhaust system in the kitchen, which allows you to use the unit directly in the apartment.

Still, most models only provide for hot smoking. This applies to mobile devices with a classic design. The advantages of electric smoking include high cooking speed and ease of use. Such installations do not require the installation of special smoke generators and produce a finished product in just a few minutes.

Functional requirements

The latest models of such equipment are equipped electronically controlled with temperature control sensors. In some ways, such devices resemble the operation of conventional kitchen stoves- the design also provides a panel with buttons and controls with which the user configures the equipment. Cold smoke treatment devices have the most complex devices. In this case, the electric smokehouse may include separate work chamber or smoke generator. This combination, for example, allows you to use the main chamber as a regular oven, and the generator for direct smoking. There are other configurations that allow the equipment to operate in different modes.

Additional equipment

Since organizing the smoking process causes a lot of trouble, manufacturers complete the equipment with auxiliary devices. For example, basic sets include trays, bowls, and smoking briquettes. Separate sets of accessories are provided for models with smoke generators. For example, a smokehouse for an apartment necessarily requires the connection of special equipment for smoke removal. For this purpose, hoses, pipes and connecting fittings are used.

Manufacturers and prices

The entry level of household electric smokers is well represented in the Greentechs and Muurikka lines. These models are different small in size, decent functionality and optimal performance indicators. These are neat devices costing about 4-5 thousand rubles, which are suitable for indoor use. If you need a multifunctional and productive electric smokehouse for your home, then you should turn to Anuka products. In this case we're talking about about models with smoke generators that cost around 10 thousand rubles. If you plan to regularly prepare food by smoking in large volumes, then units from Kocateq and Landmann will come to the rescue. A special feature of such products is the possibility of in-line work with large batches of meat, fish, sausages and sausages. We can say that these are commercial models, but there are no special restrictions for home use not expected. Of course, if the user’s home has room for a massive structure, and he is willing to accept the additional costs of energy consumption.

Conclusion

The smoking process can be performed different ways. The simplest ones include the use of ordinary metal grates and barbecues, for working with which one cannot do without lighting a fire. A smokehouse for an apartment with electrical power operates on approximately the same principles, but it also has significant differences. Firstly, the absence of the need to perform complex manipulations with firewood and ignition allows such units to be given modest dimensions. Secondly, almost all owners of such equipment note a high smoking speed, which does not impair the gastronomic characteristics of the product. And the main advantage of electric smokers is that they can be used at home - not even on the balcony, but right in the kitchen.

Unlike expensive imported equipment, which increasingly replaces natural wood smoke with synthetic liquids, your smokehouse will be as clean as a unicorn's tear. In the sense that meat, fish and sausage will gradually acquire the aroma of natural smoke from sawdust or logs. Which type of wood to choose for cold smoking is up to you to decide.

By the way, it has been proven that the most successful meat is obtained when smoked from oak and aspen, and fish - from fruit species such as cherry. Conifers are not suitable as they contain resins that spoil the taste of the product.

Second point: doing similar device with our own hands, we choose the cold smoking method, and that’s the point. When hot, the processing temperature ranges from 60 to 120 degrees, the process does not last long. This is, of course, great, since you can achieve results in a few hours. But when processed in an electric smokehouse at 20-25 degrees, the product is preserved better and is stored even longer than store-bought. So, let's get to the point.

DIY smokehouse from a 200 liter barrel

The main treasure that you will have to get is a barrel made of durable metal, preferably heat-resistant steel. Those in which explosive liquids or substances, chemicals are stored. It won’t be difficult to buy something similar in used condition, for example, through the Avito bulletin board or at the nearest wholesale warehouse metal products. Just make sure that the barrel has a lid (later it will be clear why).

And besides the barrel you need:

- Electrical cable;

- A vessel for collecting fat dripping during processing;

- A tray for wood chips, sawdust, briquettes - in a word, for flammable material;

- Thermometer;

- Metal drill;

- Chain-link mesh or lattice for product placement.

The mesh can be replaced with a system of hooks, in the end, both options can be arranged. It is important that your home electric smokehouse is as easy to use as any professional one.

Electric smokehouse drawing

Electric smokehouse assembly

Briefly, the result obtained should be as follows: an electric stove is placed at the bottom of the barrel, ventilation is done and an area for placing the product is attached. The barrel must first be washed well (you never know what was stored in it before). Next, you need to put an armful of brushwood or firewood inside and burn them to eliminate any remaining oil, and at the same time heat the walls. Only then do not forget to scrape off the carbon deposits with a metal brush and rinse well with detergent.

As the barrel dries, we place the barrel on wheels and make ventilation, for which holes are drilled in the lower part. The diameter of each circle can be 10mm, a total of 5-8 such holes are needed. Next, let's move on to the electric stove: it, in fact, only requires a heating element. Therefore, if you know how to gut a stove at home with your own hands, go for it; if not, call a specialist or just buy a heating element on the market.

An open-type heating element will act as a fire source

Using screws, it is mounted in the center of the barrel and next to it there is a thermostat with a serial connection (copper wire with a cross-section of at least 2.5 mm2). Place its sensor in a convenient place for viewing.

Then we proceed to arranging the upper part. After a short drilled hole a thermometer is attached, a tray is installed in the middle of the barrel to collect fat (an ordinary baking tray can be used). A 50mm hole must be made in the lid of the barrel to remove smoke.

Attention! The chimney hole must be closed with a damper and must be closed at the beginning of the cold smoking procedure.

The sawdust tray can also be mesh or made from a simple pan. As practice shows, one full 5-liter pan of fuel is enough to smoke for an 8-10 hour session at 20 degrees or 2-3 hours of quick “hot” smoking. Done: it is recommended to carry out the first heating for 10-20 minutes in order to “heat up” the barrel, and then you can put meat or fish into the electric smokehouse.

Below is a drawing taken from a Soviet-era magazine, a manual for amateur engineers.

The figure explains in detail the essence of how to build a smokehouse with your own hands and, due to its small dimensions, you can place it at home, but it is better in the backyard of a summer house or cottage. By the way, the camera dimensions are as follows:

- Small for smoke generation 260x240x220 mm;

- Large for smoking 340x430x220 mm.

Similar home item will be useful for lovers of smoked lard or freshly caught fish.

So, in this case, the body is prefabricated from steel sheet, although it is possible to make it from 15mm thick plywood. In this case, you need to consider fire safety, placing smoldering raw materials in a chamber lined with asbestos or other refractories. There is no need for a container for sawdust - its role is played by a smoking block, smoldering as a result of the rotation of the motor pulley. The motor runs on alternating current, and it is best to choose it with a power of 0.5 to 2 kilowatts (similar household units from broken mopeds, powerful washing machine and other equipment can be bought at a flea market).

You don't have to buy a new electric motor, check out the flea market

In order to pick up the right strength rotation for smoke to appear, use the adjusting screw, which tightens the pulley spring and presses it harder or, conversely, relieves the pressure on the block.

Naturally, the block gradually wears out, so the screw has to be adjusted and the wood periodically changed.

The chamber for cold cooking of meat or fish is located next to the smoldering chamber of the bar; they are separated by a mesh or grate. In the picture, the products are hung on hooks, but you can place, say, fillets on the grill as in the previous diagram. It is important that the separating grid is connected to a source of negatively charged particles, and the fish/meat mounts to a positive one, then the smoke will be attracted.

We see that such home smokehouse has its own magneto as a voltage source, which is connected to the motor. Scheme serial connection capacitors and their capacity are also indicated. Recommended values for an operating voltage of at least 2 kV are two capacitors of 2200 PF and a signal capacitor of 1800 PF. To ensure that the magneto is working, it is equipped with an LED light.

We hope that these two ideas will inspire you to build a similar house structure with your own hands. If you have any improvements or suggestions, please add them in the form of comments, we will be happy to take them into account!