Automation units for gas boilers AOGV Economy. Particularly important information. Date the information was entered 28.06.2015.

In general, any automation unit for gas boiler still it would be more correct to call gas valve. This name is more accurate.

We confirm our words with a quote from Wikipedia: “A valve is a device designed to open, close or regulate flow when certain conditions occur (increasing pressure in a vessel, changing the direction of flow of a medium in a pipeline).” It follows from this that the malfunction of a gas valve is precisely the possible incorrectness, unreliability, inaccuracy or complete lack of “opening, closing or regulating the flow when certain conditions occur.” But the gas valve itself may be fine, but the whole point is a malfunction of the so-called “valve equipment,” for example, or poor terminal contact. Usually, when after the third wasted (and what else!!!) call to a “specialist” the unreliability of the gas valve is not eliminated, and the causes of the failures remain unclear, there is a great desire to simply send this device to hell, replace it with a new one or something similar and more reliable.

We offer a fairly serious article on overhauling the Economy gas valve. It's called "", - always at your service. But we understand perfectly well everyone who believes that the valve must be simply and quickly replaced with a new one. After this brief introduction, you can confidently indicate the purpose of creating this article for this section: To quickly determine what type of Economy gas valve is installed on your AOGV gas boiler and give the techniques and information necessary for this determination.

To make the following material easier to understand, you may also find it useful to read:

1.

2. .

3. 4.

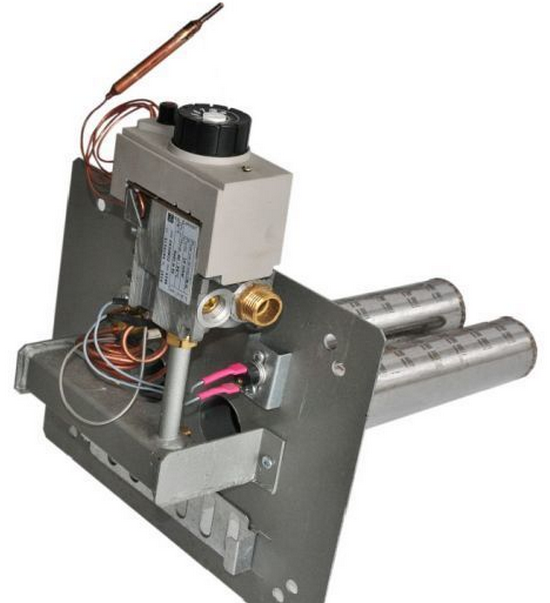

In appearance, the Economy gas valve seems like some kind of scary piece of hardware screwed to the boiler. Want to look at the granddaddy of the Economy gas valve?

The date of creation of this gas valve is unknown to us.

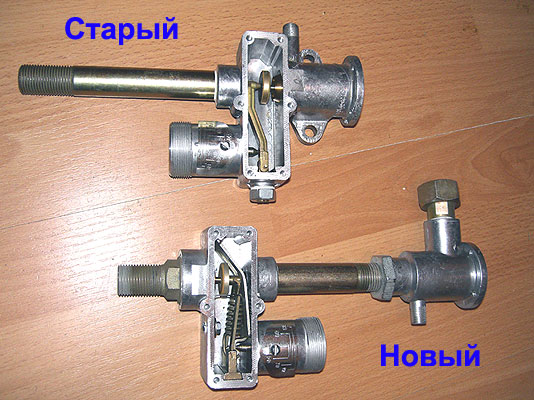

So. Economy automation units are divided into old and new, i.e. old model and new model.

Old sample. Special signs.

1. The unit has this large temperature control knob screwed on from the bottom.

2. Gas is supplied to this block as if “from behind the block”. Those. You don't have a gas hose that goes straight to the unit. And the fitting for the gas supply is located at the back of the boiler body. Gas hose connected to this fitting, which is located at the rear.

Comment on point No. 2

The fact is that gas pipe approaches the block mounted on the facade of the housing directly through the boiler itself. In fact, the idea behind such a gas supply is very wise! The idea of the designer is that the gas comes from the cold street to the block already heated. And it heats up by passing directly through the operating boiler. The vapor phase in this case is much larger. The efficiency in kilojoules is higher, which means less gas consumption. We save gas. Do you want to prove in one phrase that we are definitely saving money? It wasn't there before gas meters, but there was only an Economy gas valve. So? Therefore, one of the main tasks of the designers was to organize, precisely by the design of the valve itself and the boiler itself, the efficiency of consumption and gas savings throughout the country directly on the spot, in every house, in every hut.

Disadvantages of such gas supply to the block. Data.

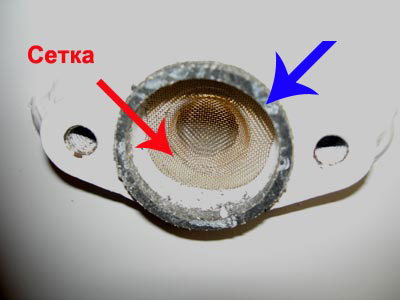

Firstly. Gas, passing through the boiler, passes to the block through the grid. This grid is located directly at the gas inlet into the block body. It is clear that in a boiler that has been operating for years, no one will ever remove the valve just to clean this very mesh. You can imagine what kind of condition it’s in if the boiler is already 12-15 years old and no one could clean it!

Secondly. Gas block is attached using a special paronite gasket. When replacing a block, it may also be necessary to replace the gasket, which, when the old block is separated, may simply fall apart due to age. We are currently trying to obtain this gasket from the factory. So far to no avail.

We call this block the old block. Why was it replaced? Our opinion Most likely, this was the case. Imagine that the pipe through which there's gas coming out through the boiler jacket, i.e. through water or through antifreeze suddenly could not ensure reliability? What will happen then? Therefore, replacing this old block with a new one is directly related to the deterioration of the quality of materials and a decrease in their durability. And this is not the fault of the plant, but the global situation itself - the desire for cheaper prices led to this replacement. Therefore, the very meaning of the ideal technology for supplying gas to the unit through a heated boiler (and it really is almost ideal) was changed and made as simple as it was abroad.

So. Again. How to determine if it is an old block? A knob (temperature control knob) and gas, which is supplied not to the block, but to a fitting located behind the boiler. Great!

Now let's move on to the power of your boiler. There are boilers with kilowatts AOGV-11.6 or 17.4, or 23.2, as well as 29.1. And all of them can be equipped with an Economy gas valve. How to determine?

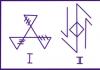

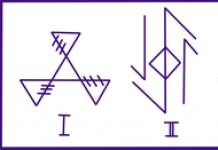

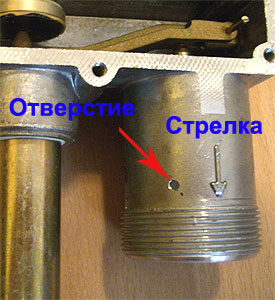

We look at the photo of two old-style blocks. The one on the left is a block for gas boilers with a capacity of 17.4, 23.2, 29.1. The one on the right is only for AOGV-11.6 boilers. Have you noticed that the blocks are identical in appearance, but there is a difference in the hole, like a slot in the body of a large fitting, into which the temperature control knob is screwed? And is there a tag attached to the fitting for the temperature control knob of one of the blocks with a screw? So here it is. The presence or absence of this hole or tag determines the difference in the blocks between AOGV-11.6, where this slot is present, and other boilers 17, 23 and 29, where this slot is not present. The presence of this slot for AOGV-11.6 is associated with the special design of the accordion of the thermal balloon bellows (explanations for those interested -), i.e. the temperature controller itself, the temperature sensor. If you want to understand this, look at how the bellows on the AOGV-11.6 is changed and you will see why this slot is needed.

Now about the tag. The tag is placed on blocks for boilers of 17, 23 and 29 kW. This blotch is nothing more than temperature scale! Just think about it!!! This is how this matter is regulated.

With the boiler running, we look at the heating temperature thermometer (if, of course, we have one?) and, turning the screw, we need to set the tag higher or lower at the temperature at which our boiler turned off. Those. We mark the shutdown temperature with this plate tag. After making such an adjustment, the temperature regulator knob moves out to the desired mark, for example +70C, and at this mark, when the temperature (indicated on the tag) is reached, your boiler turns off. Hm! Maybe now it was written a little not in Russian, but the boiler is definitely turning off!

On a block with a slot, i.e. for AOGV-11.6 there is no tag, but there is a small hole for a locking screw.

We unscrew the screw and turn the temperature regulator knob, tightening the nut approximately, lock it with the screw and look at the thermometer, and do this until we get the desired position. We combine the degrees on the nut with the arrow (here it is in the photo). If you didn’t guess correctly, then unscrew the locking screw and turn it in one direction or the other, depending on the desire to obtain the required temperature in the heating and lock the screw again. This is how we regulate this whole thing. So. Again! In addition to adjusting the temperature, i.e. slots-holes, tags and screw holes, these are the same blocks.

Old sample. Boiler AOGV Economy Zhukovsky Machine-Building Plant. Break 5 minutes. (For women - 1 hour, so they live longer than men). Children under 16 do not need a break, they do not have mental breakdown yet.)))

New sample. Special signs.

1. The most visible and main sign is that gas is supplied directly to the block. We have already said above that this design feature is associated with the exclusion of a pipe passing through the body of the boiler, through which gas is supplied to the block of the old model. So. The new Economy block has a union nut for connecting gas, and the gas flows directly into the block. To do this, the plant had to divide the body of the new sample unit into two parts. Those. we received an upper gas valve in the housing, which is directly responsible for the admission of gas to the igniter and the lower valve, and a thermostat block containing a lower valve with a fitting for screwing on the temperature regulator handle (thermal bellows). In the thermostat block, there is a change in the design of the lower valve and the “rocker arm,” as we call the lever that moves the bellows, working out the set temperature.

2. The temperature control knob (large twist) is always screwed into the new model block from the top. Looking at the price tag proposed by the factory for the entire Economy unit assembled as a new model, we smile. It is much smarter to determine which part of the block we need and purchase it. Although, we do not exclude the possibility of purchasing the entire block at once.

Results. Conclusions.

1. We know how to determine step by step the type of block: old or new. Let's define. Let's order. We change. (Don’t even think about throwing away the old block!!!)

2. We can always iterate over any block, no matter how scary it may be. In fact, this is pri-mi-tiv. And, by the way, everything ingenious is simple.

3. Compared to imported gas valves, which are not repaired, since the Economy block, we consider this block to be modern conditions the most reliable thing (no matter how funny it is for the century under No. 21), which, at least, you can ALWAYS, even while sitting in the Tundra, repair it, and there are no problems if you are ready and have the desire, even if you are only 15 years old, to feel the owner, not the consumer.

Thank you for your attention! Let's take it and do it!

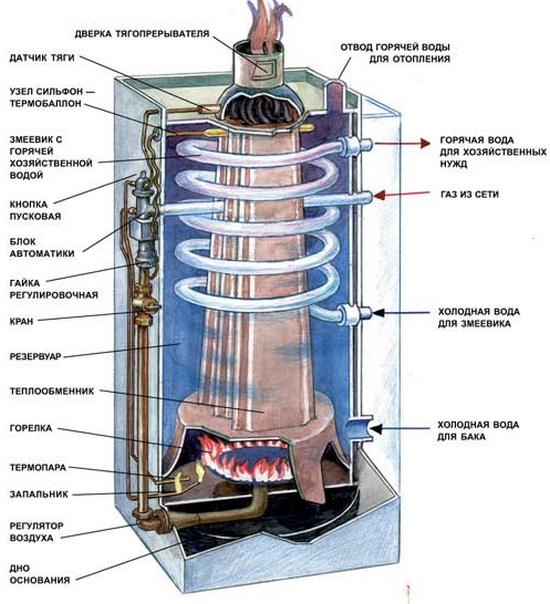

All modern heating installations, using as an energy carrier natural gas, have high level security, which is achieved through the introduction of automation tools. They control and manage the work process heating units. IN this material We will consider automation for gas boilers from the most famous manufacturers, which is most often installed on domestic and imported boilers.

Functions and principle of operation of security automation

In accordance with regulatory documents automation equipment for boiler installations must stop their operation by cutting off the fuel supply during the following  situations:

situations:

- the draft in the chimney is insufficient and there is a danger of burning;

- the gas pressure in the supply pipeline is too low or, conversely, too high;

- The flame on the igniter went out.

The listed situations can lead to the main burner going out and the room becoming gassed, which is unacceptable. For this reason, safety automatics for gas boilers must be installed on all old-style boilers where it was not provided by the manufacturer. Although it is often cheaper to replace a heater than to purchase and install automatic equipment on the old one. In addition to preventing gas contamination of the room or fumes, its functions also include maintaining the temperature of the coolant at a certain level specified by the user.

To understand how the automation of a gas boiler works, let’s briefly analyze its structure. It should be noted that both foreign and Russian manufacturers They use the same operating principle in their products, although the design of the devices may differ significantly. Automatic gas valves are traditionally considered the simplest and most reliable Italian manufacturers, which is why they occur most often.

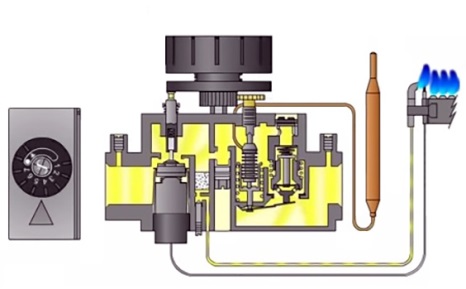

A bright representative of such gas appliances is the Italian automatic SIT, or rather, its most popular modification 630 EUROSIT, whose device is shown below.

All structural elements are placed in one housing, to which gas pipelines are connected. In addition, a capillary tube from draft and temperature sensors (thermocouples), a gas supply line for the igniter and a cable from the piezoelectric element are connected to the device. There is a cut-off inside solenoid valve, whose normal state is “closed”, as well as the gas pressure regulator and spring valve.

Any automatic gas boiler equipped with a EUROSIT or other combined gas valve is put into operation manually. Initially, the fuel path is blocked by an electromagnetic valve, which opens by pressing the adjusting washer, after which the fuel fills the chambers of the device and goes through a small gas pipeline to the igniter. While holding the washer, press the button of the piezoelectric device and ignite the igniter, heating the temperature-sensitive element for 10-30 seconds. This, in turn, generates a voltage that keeps the solenoid valve open, after which the adjusting washer can be released.

Then everything is simple, we turn the washer to the required division and thereby open access of fuel to the burner, which is independently ignited by the igniter. Since the automation of gas boilers is designed to maintain the set temperature of the coolant, human intervention is no longer required. The principle here is this: when heated, the medium in the capillary system expands and acts on the spring valve, closing it when it reaches high temperature. The burner goes out until the thermocouple cools down and the gas supply resumes. You can study the operation of Italian SIT automation in detail by watching the video.

Brief overview of products from popular manufacturers

The second place in popularity among foreign gas valves after the “Italians” is confidently occupied by American-made Honeywell automatics. The simplest budget model combined device works on the same principle as EUROSIT and has the same set of functions.

Under this brand there are other types of automation on the market for gas boilers and others. gas installations with advanced features. For example, the Honeywell VR 400 model is equipped with two valves with a servo drive for operation with electronic units control of gas boilers or remote controllers. The device has the following additional functions:

- smooth ignition system;

- modulation operating mode;

- built-in mesh filter;

- maintaining the burner mode “low flame”;

- additional outputs for connecting minimum and intermediate pressure switches.

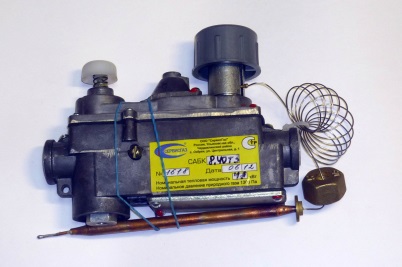

Considering the operating conditions in the post-Soviet countries, the installation of automation on a gas boiler, which is adapted to these conditions, does not lose its relevance. Such devices are offered by many Russian manufacturers, among them Orion combined gas valves and SABC automation deserve attention. The latter is manufactured by the ServiceGaz company (Ulyanovsk), and the range of products for gas installations is very wide.

It includes both the most simple devices security with a minimum set of functions, as well as equipment sets that include several units: control, power and gas burner. SABC brand products are well known to consumers for their affordable cost and maintainability.

Installing SABC

Orion automation is also widely popular, namely the Orion - 16 and Orion - 20 models for household boilers. These 2 products use the same principle in their work with a thermocouple, solenoid valve and piezo ignition, only in addition to the main functions, these devices can support low flame mode burners when reaching set temperature coolant. The range of their application is gas boiler installations with a power of up to 32 kW.

Conclusion

Modern automation for gas boilers plays a significant role in safe operation heating equipment, now it’s impossible to do without it. Another thing is that more expensive Italian and American devices are highly reliable and durable; this has been tested over years of operation on various water heating installations.

Malfunctions of the Zhukovsky boiler AOGV-23 and their elimination

Pressing the start button fails to ignite the igniter; the flame on the igniter goes out and comes off

The gas tap in front of the device is closed - Open the gas tap.

The hole in the igniter nozzle is clogged - Clean the hole with Ø 0.3 mm wire.

Gas pressure below 635 Pa (65 mm water column) - Notify the gas department.

The presence of strong drafts in the room, leading to the flame breaking off on the igniter - Eliminate or reduce drafts.

There is no spark between the spark plug electrode and the igniter

Large gap between electrode and igniter - Adjust the gap.

Piezo ignition does not work - Replace piezo ignition.

When the start button is released (after holding it for at least a minute with the igniter burning), the igniter flame goes out

Oxidation of the solder on the contacts at the junction of the electromagnet with the contact wire, weak pressing of the pins in the sockets - Unscrew the fitting of the contact wire from the gas magnetic valve body, clean the contact with a file until shiny (remove the oxide film).

Screw the fitting back into the housing. Remove the sockets from the pins and lightly crimp the sockets with pliers. Install the sockets onto the pins.

To avoid breaking the soldering of the electromagnet contacts and the contact wire, do not overtighten the wire fitting when screwing it into the gas magnetic valve body.

The traction sensor microswitch does not work - Replace the microswitch.

The thermocouple does not produce EMF, the end of the thermocouple has burned out (the value of the thermocouple EMF must be at least 20 mV) - Replace the thermocouple.

The igniter flame does not touch the thermocouple - Install (bend) the thermocouple so that the flame washes the end of the thermocouple (see Fig. 3).

The safety thermostat is faulty - Replace the safety thermostat.

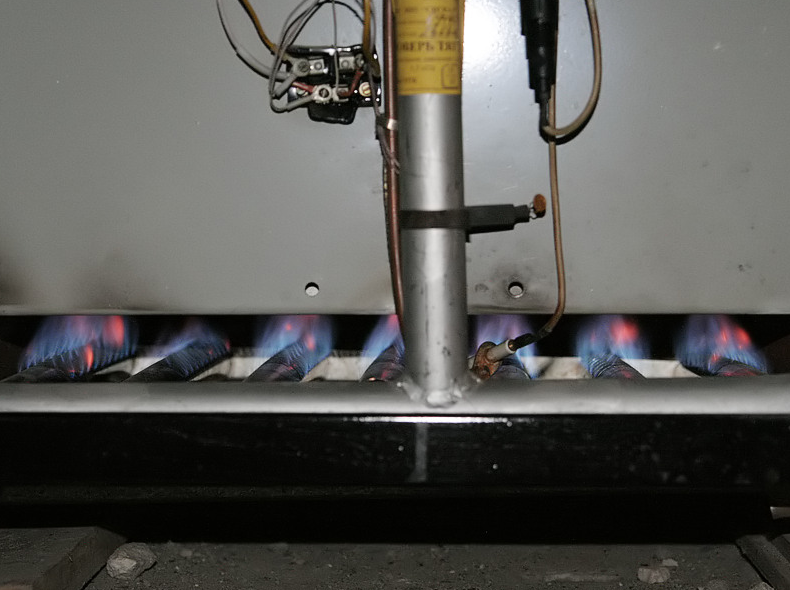

The flame of the burner and igniter goes out. Automatic shutdown of the gas supply when the gas boiler AOGV-23 ZhMZ is operating. The traction sensor is triggered

Complete or partial blockage of the chimney - Clean the chimney.

The presence of strong drafts in the room, leading to the flame failure on the igniter - Eliminate or reduce drafts.

The pressure has dropped below 635 Pa (65 mm of water column) - Notify the gas department.

To measure the gas pressure in the network, disconnect the igniter tube from the fitting of the valve body. Connect a measuring device to the fitting.

Turn the adjustment knob, setting it to 50 - 60 °C. Press the start button all the way, then release it 2 - 3 mm and after 8 - 12 seconds. take readings from the device.

The response time of the automatic operation of the gas Zhukovsky boiler AOGV-23 for draft is less than 10 seconds. in the absence of draft in the chimney.

The automatic response time for traction is more than 60 seconds. in the absence of draft in the chimney.

The draft sensor is not adjusted - Adjust the sensor by: unlocking it, unscrewing (or tightening) the adjusting screw by 1-2 mm and locking it again. Check the response time. Repeat the operation if necessary.

The response time depends on the size of the gap between the adjusting screw and the microswitch button. As the gap increases, the response time increases and vice versa.

The main burner does not turn off

The bellows-thermal cylinder is depressurized - Replace the bellows-thermal cylinder

Thermostat is out of adjustment - Adjust the thermostat in the response ranges within 50-90 °C.

Burner does not turn on after switching off long time. The water in the tank is hot, the batteries are cold

No circulation in the heating system - Eliminate backslopes in the heating system. Eliminate air pockets in the heating system.

Presence of flame at the fire holes of the main burner when the thermostat is turned off

Leakage of the thermostat valve due to dirt - Remove the front thermostat cover. Clean the valve plug and apply sealing lubricant.

The draft breaker door does not rotate or rotates slowly

Presence of dirt on the door axle - Remove dirt from the door axle and the socket for installing the axle in the traction breaker body.

___________________________________________________________________________

Automation for gas heating boilers ensures stable and safe work equipment. These systems significantly simplify the use of heating equipment, increase its operating efficiency and allow for the rational use of energy resources.

Automation for gas boilers AOGV

Modern models of heating boilers are equipped with devices automatic type in production. Automation must ensure an uninterrupted supply of gas to the burner, but the functions of these devices are not limited to this. Automatic devices shut off the gas supply valve in potentially dangerous situations:

- The water temperature in the boiler tank exceeds the set maximum.

- The igniter goes out.

- The water supply stops.

- There is a failure in the gas system.

- The pressure drops below the established norm.

- In case of insufficient chimney draft.

What does the automation system for gas heating boilers AOGV consist of?

Standard automatic system must have several basic elements.

Ignition elements. IN modern systems there is no burning splinter. The pilot burner is ignited using a piezoelectric element, which produces electrical energy as a result of mechanical pressure on the crystal. There are systems in which you need to open the gas supply valve with one hand and press the piezo ignition button with the other. In the most modern boilers, one button is responsible for the operation of both processes. The gas valve is then controlled in one of two ways:

- Due to the voltage that occurs when the thermocouple heats up.

- Due to heating of an additional thermal generator (more often used in imported boilers).

Automation of gas boilers AOGV most often operates using thermocouple energy.

In both cases, the generated energy creates a voltage that acts on the gas valve coil. It remains open, providing gas supply, as long as the gas burner is burning.

Thermoregulation system. These elements control the water temperature. They consist of a temperature sensor and a valve system that shuts off the flow of gas when the set temperature is reached. In the most modern models boilers have been added to the control scheme room thermostat, which, depending on the room temperature, gives a signal and the need to close or open the gas supply valve.

IN mechanical system thermoregulation there is a thermometer on the control panel, and the temperature regulator is located at the coolant outlet from the boiler.

Elements of control over effective and safe deletion combustion products. This is a draft sensor that is mounted in the chimney. Wires connect the draft sensor to the gas valve. If there is no optimal draft, a signal is sent to the valve, it closes and stops the gas supply.

- Automation for gas heating boilers does not allow you to turn on the gas supply if the equipment’s performance indicators go wrong or the slightest breakdown or depressurization of pipes occurs.

Additional elements and automation capabilities

In some models, automatic equipment for gas boilers AOGV is equipped with a thermostat that provides regulation of gas flow. The reason for reducing the intensity of work may be an increase in temperature outside or a signal from the thermostat in one of the rooms that the maximum permissible temperature has been exceeded.

- Models that are mounted in the system " Smart House", suggest the possibility remote control heating modes.

A modern, properly installed and adjusted automatic system on heating equipment helps reduce heating costs by 40%.

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

Old-style boilers were manufactured in accordance with the gas parameters and heating system features that were in use several decades ago. These are, for example, models KChM, AOGV. At the same time, their strength makes it possible to use them even more. long years. But the problem with automation is that quite often it breaks down. In such a situation, there are three options:

- diagnose existing automation and replace the necessary parts;

- equip a reliable and high-quality unit with a modern automatic system;

- buy a new boiler.

The difference, of course, is in the price of the issue, the effort and time of the owner.

Let's consider the most cheap option– troubleshooting gas automation on an old boiler. However, first, let’s figure out why an automatic system is provided in the coolant in general.

Gas automation allows you to regulate and maintain required level coolant temperature, and also serves to automatically stop the gas supply in an emergency situation. Installing automation on an old gas boiler will allow you to be sure that if the burner flame goes out, then after a short time the system will work to stop the gas supply without your participation.

Attention!

Automation, in addition to regulating and maintaining the temperature at a given level, ensures safety of use heating device and allows you to save on heat consumption.

If you want to change the automation, keep in mind that domestic manufacturers produce models that are suitable for almost any old coolant. Imported automation cannot be installed on everything. In addition, when installing foreign automation on old-style gas boilers, not all of its functions may work - they will not allow design features boiler

On a note!

The choice of automation for gas boilers is varied. The most popular is the system from Italian manufacturers, for example, SIT. American automation (Honeywell) holds second place in popularity. There is a large selection of Russian (SABK, Orion) and Ukrainian manufacturers (Fakel, Iskra, Plamya, APOK-1).

The principle of operation of automation on old-style gas boilers

Frequent problems when heating a room gas boilers are flame attenuation in the burner and gas pollution in the room. This happens for several reasons:

- insufficient draft in the chimney;

- too high or too low pressure in the pipeline through which gas is supplied;

- the flame on the igniter goes out;

- leakage of the pulse system.

When these situations arise, the automation is triggered to stop the gas supply and prevent the room from becoming gas-filled. Therefore, installing high-quality automation on an old gas boiler is basic safety rules when using it to heat a room and heat water.

All automation of any brand and any manufacturer has one operating principle and basic elements. Only their designs will differ. Old automatic machines “Plamya”, “Arbat”, SABC, AGUK and others work according to to the following principle. When the coolant cools below the temperature set by the user, the gas supply sensor is activated. The burner starts heating the water. After reaching the user-specified temperature on the sensor, automatic shutdown gas sensor.

On a note!

When using modern automation, it is possible to save heat up to 30%.

Old-style automation is non-volatile and does not require electricity. Its adjustment, connection and disconnection are carried out by a person. Commands are transmitted using electromagnetic pulses.

The video explains how the automation of gas boilers AOGV and KSTG works.

Basic elements of automation

The main elements of automation for a gas boiler are:

- thermostat;

- shut-off valve;

- traction sensor;

- flame sensor;

- igniter tube;

- igniter;

- burners.

Let's try to clearly explain how automation for a gas boiler works, breaking it down into its main elements and talking about their functions.

The gas passes through a gas purification filter. Next it goes to the solenoid valve, which regulates the fuel supply to the burner. Temperature and draft sensors are located next to the valve, monitoring the indicators and signaling when they go beyond acceptable standards. Also, the automation kit for gas boilers includes a thermostat with a bellows and a rod, designed to set the desired temperature. A special button is used to adjust the indicators. When the water is heated to the temperature set by the user, the thermostat is activated, the gas supply to the burner is stopped, while the igniter continues to operate. When the water cools by 10-15 degrees, the gas supply is resumed. The burner lights up from the igniter. The automation is started manually.

Flame and draft sensors

Flame and draft sensors work on this principle. The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.

The most common automation malfunctions and methods for eliminating them

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that will require specialist intervention. The adjustment can also be entrusted to a gas technician. Or you can do it yourself by reading the instruction manual.

Attention!

Before each seasonal operation, it is necessary to check the operation of the safety sensors.

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected. The filter must be properly cleaned by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler.

In order to replace the temperature sensor, you need to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, remove the PTV adjustment screw. Remove the sensor bellows with the support washer. Unscrew the union nut of the sensor thermal bulb. Install the thermal bulb of a working sensor into the boiler jacket and screw it tightly. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If problems arise with ignition of the igniter, then one of the possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, checked contacts, cleaned, and, if necessary, replaced with a new one.

Also common reasons Why the igniter does not light could be:

- gas valve malfunction;

- clogging of the hole in the igniter nozzle (it can be cleaned with wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, and the gas pressure at the inlet to the gas boiler.

Attention!

To diagnose and repair the gas boiler automation, you must invite a specialist. Inept actions can aggravate the problem and lead to undesirable consequences.

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensing element.

In Arbat and Orion, you can only replace the thermocouple and draft sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In Arbat, the system shutdown button often breaks down.

Typical problems for SABC automation are damage to the main valve membranes and drying out of the thermostat stuffing box, resulting in gas leakage. Subject to control impulse tubes, bimetallic plates, ball valves.

In conclusion, I would like to emphasize once again that automation is designed to maintain the operation of heating equipment in a safe mode. Therefore, it is simply necessary for owners of gas boilers.

This video shows how to troubleshoot an automatic boiler AOGV, step by step process assembly and testing of the result.