Smoking, as a method of food preservation, has been known for a very long time. Today, it has not lost its relevance, and not so much because of the long shelf life, but because of the taste that the product acquires. In this article, we will talk about how to make a smoke generator for cold smoking with your own hands.

Traditional cold smoke smokehouse

Regardless of the type of smoking, the source of smoke is a fire. With cold smoking, the main thing is that the smoke is cold or warm, but not hot. The maximum temperature is about +40°C. To do this, a fire is bred a few meters from the smoking cabinet, a pipe is laid between them - a chimney. Passing along this path, the smoke cools down to acceptable temperatures.

The installation of a chimney is a lengthy process. The smoke path must ensure normal heat removal and must be airtight at the same time. To create a chimney, you can use a standard metal chimney (but not made of galvanized steel), but in order for the smoke to cool better, it is advisable to bury the pipe in the ground. All in all, not an easy task. That is why they prefer to make a hot-smoked smokehouse - fewer problems - they installed a barrel over the fire and smoke ...

But there is a simple smoke generator for cold smoking, which will cost literally several thousand. But to work, you also need the ability to handle it. Everything else can be bought on the market or in a hardware store. If you have all the components, you can assemble a smoke generator for smoking with your own hands in an hour or two.

A simple do-it-yourself smoke generator for cold smoking

If you do not need production volumes, you can make a small and uncomplicated smoke generator from a metal pipe. A body is made from a pipe, into which sawdust or shavings are stuffed. The shavings are lit from below, the smoke rises up, where it is discharged with the help of a welded pipe into the smoking chamber. To increase traction, a low-power compressor is connected in the upper part of the case - with a capacity of 1.5-2 liters / min. That is, you can use an aquarium compressor or a unit from an old refrigerator. If there is a choice, then the aquarium is preferable, since they can regulate the intensity of the smoke output.

At the outlet of this smoke generator, the smoke is slightly warm. The source of ignition is very small, the fire spreads slowly, the resulting smoke slowly rises through the sawdust. It cools down, the sawdust dries up. In general, everything works perfectly.

materials

For the body of the smoke generator, you can use:

- round pipe with a diameter of 80-90 mm;

- profiled pipe with a side of 80 mm or more.

The larger the cross section, the more sawdust can be placed inside, the longer the smoke generator for cold smoking will work on one tab.

The length of the pipe is 60 cm or more. Optimally - about 1 meter. Again, the larger the pipe, the more fuel can be laid. On the other hand, a smoke generator that is too large is inconvenient to fill and clean, as it turns out to be heavy and bulky.

Cold smoked smoke generator - one of the options

You will also need a 3/4 inch pipe - a piece of 30 centimeters or more. Tube 1/4 inch or so. Its length is selected already in the finished state, but 20 cm should be enough.

Still need a grid. It can be any metal mesh with a cell of 2-3 mm or a plate with frequent holes. For the legs, find small pieces of bar/rebar/metal strip. Some designs do without them, but with them the design is more stable.

You also need a compressor with a capacity of 1.5-2 liters / min, preferably with the ability to adjust performance. Aquarium compressors meet these requirements. And you need a fitting so that you can connect the pipes from the compressor through it.

Assembly

We will describe a smoke generator for cold smoking based on a profile pipe with a cross section of 100 * 100 mm. With a round pipe, the process is almost the same, but it is more difficult to weld pipes, if you have little experience in welding work, it is better to use a profiled (square) pipe.

- At a distance of 2 cm from the bottom edge of the grinder, we make cuts on two opposite sides.

- We cut out a square from the grid, slightly larger than the pipe section. We insert it, fixing it in opposite cuts.

- On the other side, weld a piece of 3/4 inch pipe.

- Strictly opposite, it is necessary to weld a fitting for connecting the compressor. It must be positioned so that its center coincides with the center of the already welded three-quarter pipe.

- Now we take a thin tube. It must be inserted into the fitting, it must pass through the body and enter the tube opposite by 1 cm. No more, but no less. Air from the compressor enters through this tube. By creating thrust, it stimulates combustion. By adjusting the power of the compressor, the intensity of the smoke output is regulated.

- We make a cover. From a piece of metal we cut out a square, slightly larger in size than the section of the body pipe. We make a hole in the center, install the handle. Preferably wooden. Although the smoke is not hot, but the body is heated by the "bonfire" that burns in the lower part. Such a cover is not very convenient, as it flies. Having outlined the contour of the pipe, we retreat from the resulting line a couple of millimeters and weld a strip of metal 1 cm wide or so. This cover doesn't come off.

- From below, where the mesh is fixed, we weld four pieces of rod / reinforcement. These are legs.

That's all. Homemade smoke generator for cold smoking. Ready. It can be experienced. For ease of use, you can still weld the legs. And remember that coals and ashes will spill out through the grid, so you need to install a smoke generator for cold smoking on a non-combustible site.

How does it work

Dry shavings are laid in the pipe. You can use sawdust, but then a spring is put on a thin tube located in the upper part, which reaches the mesh itself in length. The condition and quality of the spring is not important. Its diameter is important - about 2 cm. Why is it needed? For activation of combustion and normal smoke output.

When the case is filled with sawdust, they lie tightly, making it very difficult for smoke to escape, the air suction is very weak, everything barely burns. The spring is also needed to activate combustion. Smoke comes out through it, a draft is created (from the grid - through the spring - to the outlet pipe.

Set fire to the bookmark from below - through the grid

After filling the body with sawdust, they are set on fire from below. This can be done with a gas burner by tilting the smoking smoke generator on its side. When the chips start to burn, put on the lid, turn on the compressor. If the shavings/sawdust are dry, the stasis smoke begins to actively enter. That's all. You made a smoke generator for cold smoking with your own hands.

Modernization

The design described above is fully functional. But it has many shortcomings, not very convenient. Based on the results of its use, improvements and improvements were made.

Adjustable traction

One of the main disadvantages of the described design is the poor regulation of the intensity of combustion. It can be slightly changed by adjusting the compressor capacity. An adjustable blower can be added to the design. It can be done according to the principle of the gate:

Everything, the adjustable damper is ready. Turn it, adjust the intensity of air intake, adjusting the intensity of combustion.

Ash pan

Another drawback is that ash wakes up through the grid. You can put the smoke generator on a metal plate, but you can make an ash pan. By the way, the gate can be made in an ash pan. This will be more correct, since the air leakage can be almost blocked, which you cannot achieve with a gate in the housing - air enters through the grid.

Ash pan - a small container slightly larger than the body

The ash pan is made from a piece of pipe with a slightly larger cross section than the pipe on the body. If you don't have one, you'll have to weld it. The bottom is welded to a piece of pipe, a thin strip of metal is welded to the body along the perimeter. The body is inserted into the ash pan (the legs are also welded to it).

Condensate collection

During the operation of the smoke generator for cold smoking, condensate is released. This complicates life, especially if the temperature outside is low. You can solve the problem by making a collector for condensate. For this:

With such a device, a significant part of the condensate is in the tank. The problem is not so acute.

The simplest smoke generator from an electric stove

If you need smoked meats “right now”, you can use a very simple method: you need an electric stove, a barrel without a bottom or a piece of large diameter pipe, a wire mesh with a cell of at least 10 * 10 cm, a sheet of plywood or iron. Still - sawdust and "object of smoking".

Such a cold-smoked smokehouse is usually placed on the street, in the backyard. It is necessary to clear the patch of vegetation, install an electric stove. On it - a metal container (which is not a pity to throw away). Sawdust is poured into the container.

In the upper part of the barrel / pipe, stepping back from the upper edge of 10-5 cm, we drill four holes. They are located diametrically or opposite each other. We put pins in them. You can use metal rods, you can use sticks. The choice depends on the weight of the products to be stacked or what is available. The rods themselves can be arranged crosswise or as two parallels, located approximately 1/3 of the diameter of the smokehouse body. On top of this support we lay a grid, with products attached from below. We cover the smokehouse with plywood or a sheet of metal.

Turn on tiles. After a while, the sawdust starts to smoke. The time of "work" on one tab depends on the amount of sawdust poured, but on average it is 3-5 hours. Then you have to set aside the body, add sawdust, put everything in place. Difficult, uncomfortable and fraught with "accidents". But the design is very simple, it is a "camping" option, which does not imply amenities.

Another disadvantage is to regulate the intensity of the smoke with a mono tile regulator, but doing it in this form is inconvenient - again, you have to move the case. You can get rid of these shortcomings if you make a door below. With its help, it will be possible to regulate the air flow and change the sawdust.

Smoke generator for cold smoking

If a higher capacity installation is required, a simple stove is brewed. It can be made from the same large diameter pipe or a rectangular case can be welded from metal. Weld the door, make a chimney fixed at an angle. That's all the difficulty. It is also necessary to divide the internal space with a horizontally fixed metal sheet into two parts. The bottom is bigger, the top is smaller. A fire is kindled below, sawdust is poured onto the sheet. Further, the process is known.

A pipe is laid from the stove chimney to the smoking cabinet. It should have an upward slope, albeit a small one. In this case, the entrance to the cabinet should be located at the bottom - so that the smoke envelops all products. Therefore, the cabinet is installed on a dais, legs, pedestal. To save space, you can install the smoke generator stove under the cabinet by welding the structure from a metal corner.

Smoke generator - freestanding stove

But with this design, the smoke can be too hot. Additional measures are needed to cool it down. As an option - find a pipe of a larger diameter, put it on the main chimney. Install the cooler so that the air flow is directed into the gap between the pipes.

Another option is to do something like a water jacket, getting hot water while smoking. But where to put it is the question. Although, warm water in the household is always useful.

A smoke generator for cold smoking of this type is more expensive - metal or a thick-walled pipe, plus a chimney. Moreover, it is better not to make a chimney from galvanized steel - zinc is not the metal that is good for health. Asbestos should not be used either. Firstly, it does not remove heat well, and secondly, it is even more harmful than zinc. Therefore, the choice in this regard is small - order pipes made of black steel or buy stainless steel. Here everyone decides for himself.

Related videos

Scientists from the Institute of Nuclear Physics and the Institute of Cytology and Genetics of the Siberian Branch of the Russian Academy of Sciences proposed using industrial accelerators created at the institute for disinfecting wastewater from pig farms and poultry farms.

Industrial accelerators - charged particle accelerators used in industry. The Institute of Nuclear Physics SB RAS has been producing two types of particle accelerators for 40 years: electrostatic and high-frequency impulsive. During this time, more than 220 installations have been collected. They can be used in various areas: for the disinfection of medical clothing, for imparting new properties to materials, X-ray flaw detection, obtaining metal nanopowders, etc.

INP Deputy Director Gennady Kulipanov told how accelerators can be used to treat wastewater from the Kudryashovskaya pig farm.

“It is known that a colossal smell emanates from the Kudryashovsky pig farm, it also discharges wastewater into the Ob and pollutes groundwater. Together with ICIG, we have developed a comprehensive method of wastewater disinfection, which uses a water hyacinth plant that filters water and absorbs all solid fractions onto itself, then it is cut off, irradiated and used as fertilizer. Water can be used in the second circle,” Kulipanov said.

He explained that a similar technology could be used to treat waste from poultry farms.

Kulipanov said that the project required investments and did not receive support at the regional level, but it was sent for consideration to the Russian Ministry of Agriculture.

The scientist said that with the help of particle accelerators in the 1980s, they managed to solve the environmental problem in Voronezh.

“The waters of Voronezh were cleared of organic matter, which appeared due to the work of a synthetic rubber plant. Due to the imperfection of processing technologies, the waste was simply pumped underground, and it leaked out. It was the world's first such technology - water was pumped out of the ground, irradiated at the accelerator and pumped back. From 1984 to 1988, the pollution spot decreased, the sands were washed several times,” Kulipanov said.

He added that such an accelerator with a capacity of 500 kilowatts was bought from the institute by the Koreans for the treatment of wastewater from chemical plants.

Recall that with the help of industrial accelerators, proteins can be “sintered” in a special way, which allowed Novosibirsk scientists to create a unique medicine for the treatment of blood clots.

Source: sib.fm

ABH Miratorg launched a biocomplex for deep wastewater treatment at the Kurasovsky pig farm (Ivnyansky district of the Belgorod region) worth 7 million rubles and a production capacity of 360 cubic meters per day, the company's press service reported.

According to the general director of the company's pig farms in the Ivnyansky district, Alexei Yudin, the main function of this unit is the separation of solid particles from livestock effluents with liquid. He explained that such measures will not only reduce the shelf life of wastewater in the lagoons, but also "increase the efficiency of biological treatment", as well as minimize the impact on the environment, primarily "in terms of the spread of unpleasant odors."

Recall that the Kurasovsky pig farm was launched at the end of January 2004. The construction of a biocomplex for the separation of liquid and solid fractions of livestock effluents was launched in the fall of 2013. Today the complex is operating at full capacity.

Miratorg is a vertically integrated holding that includes two grain companies, three elevators, four feed mills, 23 automated pig farms in the Belgorod and Kursk regions, a high-tech enterprise for slaughter and primary meat processing, a plant for the production of semi-finished products, a logistics company, distribution centers in large cities of Russia. The production capacity of the meat processing plant in the Belgorod region is 3 million heads per year.

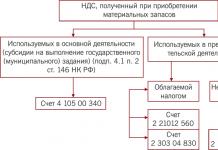

For more efficient cleaning in the H10-IDG-1 smoke generator, a water-inertia method is used. Its essence is as follows (Fig. 49). The flow of smoke generated in the smoke generation chamber is directed along the central pipe and, by inertia, hits the water mirror, displacing part of it from under the end of the pipe. Further, the smoke enters the knee and again hits the surface of the water. At the points of contact of smoke with water, it swirls and a water-smoke mixture is formed. Due to inertia and effective contact with water, heavy smoke particles (soot, ash, tar) are captured by it. Running water carries away soot and ash particles, and the resin settles to the bottom of the device and is periodically removed through the hatch into a special container.

Other solutions can be used to reduce the PAH content in smoking smoke and, accordingly, in processed products. For example, a water curtain is provided in the H20-IHA.03 smoke generator. There are also known methods for removing PAHs from smoke by lowering the temperature, passing it through metal shavings, sawdust and a layer of water, or by obtaining smoke condensate, which is transferred to a state close to the original smoke before being sent to the smoking chamber. When converting condensates into a vapor state, the heating temperature plays a significant role in reducing the content of PAHs. So, at a temperature in the range of 294-316 °C, the content of benzo(a)pyrene in the newly formed smoking medium decreases by 14-17 times compared to the original smoke, and at a temperature of 371-427 °C - by more than 100 times.

All considered methods have a common drawback - they do not solve the main problem of completely eliminating the possibility of contamination of smoked products with PAHs. It should be noted that research is currently being carried out to prevent the formation of PAHs in smoke by pre-treatment of sawdust with chemical reagents that reduce the temperature of the thermal decomposition of wood.

Various types of smoking have long been used for heat treatment of various types of products. Smoking is not just a way to make a dish with a longer shelf life from a perishable product, it is also an opportunity to give food delicious aroma and taste. Despite technological advances in terms of food preparation, cooking with the help of smoking is still relevant and in demand.

Cold smoking - basics and principles of the process

The fundamental role in smoking is played by the smoke entering the product, which gives the finished dish an incredibly appetizing smell and amazing taste. On sale today there are many options for smokehouses, but not everyone can afford them.

So that the family budget is not damaged, and you and your loved ones can enjoy self-cooked smoked meats, you can do do-it-yourself smoke generator.

Cooking cold smoked products is not a quick process, but it does not require special skills.

Conditions to be observed during cold smoking:

- products before smoking must be processed - cleaned, washed, salted and dried a little, dried;

- smoke treatment of products should be long - it takes from several hours to 5 days;

- the temperature of the incoming smoke should be minimal;

- mainly sawdust from fruit trees is used, but in no case from coniferous trees, otherwise the dish will be hopelessly spoiled.

The process of cold smoking includes many different subtleties and nuances that you should learn. Depending on the skills of the cook and the accuracy of compliance with the requirements for smoking, the result will also differ.

Even a smoke generator (especially a homemade one) has a significant value - depending on its design, there will be vary the intensity of smoking and, accordingly, the result.

The most important thing in a smoke generator is the correct arrangement of all parts and the flow of low-temperature smoke. It is thanks to compliance with these requirements that the products acquire a presentable golden color and become incredibly tasty.

The smoke in the generator is formed from sawdust (sometimes chips), and it is recommended to use certain types of wood:

- cherry;

- alder;

- Apple tree;

- pear.

Taste, aroma and color characteristics of the dish will be different if you use one or another wood. By assembling a do-it-yourself smoke generator for cold smoking, you will have complete freedom in cooking experiments and will be able to develop your own signature recipe.

How to make a smoke generator for a smokehouse with your own hands

Smoke generators may be different, but in general their designs do not have any special differences. They consist of:

- heat source;

- fuel;

- smoke cooling systems;

- systems for supplying cooled smoke to the smoking tank.

Before deciding on the model of a smoke generator for a smokehouse, you must select heat source. It could be:

On your own site, it will be most practical to use other options as fuel for a smoke generator for cold smoking. The best option, of course, is sawdust - you can prepare them yourself or purchase them ready-made.

How to make smoke cold

Smokehouses for cold smoking have the same design:

- A hole is pulled out and lined, which will be a firebox.

- The chimney is laid underground.

- A filter is installed to prevent soot from entering the products.

- The smokehouse itself is installed.

But often there are problems in the form insufficient smoke cooling, that is, the products are cooked at a high temperature and instead of cold, hot or semi-hot smoking is obtained. You can solve this case like this:

- Lengthen the chimney so that the smoke passing through it cools down.

- Use running water to cool the passing smoke in the generator. For this option, it will be necessary to modernize the source of smoke: sawdust is poured into a container (a tin can, for example) and it is covered with tiles. If the distance from the firebox to the smokehouse exceeds a meter, then additional cooling is not needed.

Electric generator for smokehouse do-it-yourself cold-smoked is going to be as easy as shelling pears. In this case, an electric stove serves as a heating element, and the smoke is cold due to a sufficiently long pipe.

Electric generator for smokehouse do-it-yourself cold-smoked is going to be as easy as shelling pears. In this case, an electric stove serves as a heating element, and the smoke is cold due to a sufficiently long pipe.

wood smoker also assembled in the simplest way. The source of smoke in this embodiment is a potbelly stove. The smoke is cold due to the number of bends (elbows) of the pipe and its length.

Assembling a smoke generator with your own hands for the production of cold smoked products at home is a simple task, but it requires a careful approach. Be sure to follow the fire safety rules so that cooking is a joy and the resulting dishes are a pleasure.

Smoked fish or bacon in a hot way in the country, in camping conditions or even in a city apartment is within everyone's strength, but with cold smoking everything is much more complicated. Here you can not do without a stationary smokehouse and strict adherence to technology. And how many different subtleties need to be taken into account in order to end up with the “correct” ham or fish delicacy! Many Forumhouse users have successfully mastered smoking with a smoke generator and are happy to share their experience and successful recipes.

How to make a smoke generator

The sale is now full of smoke generators and fully equipped smokehouses for every taste. But a good purchased unit is quite an expensive pleasure, it is easier to make it yourself from improvised materials. The main thing is to know how to do it right. A proven working option is suggested by the user vital.

– The smoke generator is made in the form of a long pipe for a number of reasons. The main one is the slow burnout of sawdust. You can stretch one charge for the entire smoking process, just after a while, rearrange the lamp or burner a little along the length of the pipe. On the pipe, the heating spot will be optimal. You can’t get this with a pot / stove, and the smoke will go in charges (as it warms up, it starts strong, then a gradual decline). You will have to monitor the sawdust and change them quite often (the HC process is protracted). Then, with a fire (or potbelly stove) it is not very convenient to monitor the temperature, you constantly need to control the combustion processes.

No matter how good the recipes for smoking meat are, the smoke generator, “scrambled” from junk, can ruin everything.

An iron barrel (and not some box upholstered with insulation) also plays an important role in cooling the smoke. It is desirable to make joints on the thread - the design must be disassembled, especially the back cover, to charge the smoke generator through it. It remains to make a couple of holes in the barrel, buy a temperature sensor. And everything is ready for operation. This version of the smokehouse is winter, for the cold. At higher temperatures, it is necessary to make an additional smoke cooler (either on the pipe or in the chamber itself, i.e. barrel).

And here's the user's version Captain777. Checked - cold smoking with a smoke generator works fine.

Captain777:

- The generator is connected to any cabinet or barrel with a pipe, corrugation, etc. No need to build meter-long chimneys for cooling, the smoke is slightly warm at the exit. A rectangular metal container where sawdust chips are poured, at the bottom there is a hole with a plug for ignition and the second one for supplying air from a compressor (you can use it from an aquarium or, as in my photo, from an old refrigerator). "Charge" is enough for several hours.

Its simple but effective design of the smoke generator offers Semur. The unit, according to him, is assembled literally on the knee - cheap and cheerful.

- The generator works from chopped wood chips: wood chips were poured into a vertical pipe, set on fire from below, a hose from an aquarium compressor - i.e. air draws smoke through a horizontal pipe, at the same time creates traction, shavings smolder, cold smoke comes out. 4-5 hours work. Not enough - I lengthened the pipe, and the time lengthened, it will smoke for 8-10 hours. The price of the issue is five electrodes, a plumbing fitting + squeegee + pipe, better weaving in diameter (wood chips will not get stuck).

Smoking with a smoke generator: recipes

Cold smoking is a serious and time-consuming matter, and in order to learn how to cook delicious foods and minimize the harm to health from their use, members of the forum are advised to carefully study all stages of the process. It would not be superfluous to familiarize yourself with the sanitary requirements for smoking ovens and cold smoking technology. Nothing can be simplified here, it is important to strictly observe the temperature and time regime. Well, to know the "correct" recipes. This is how a forum member smokes poultry and meat DeRenarardNez.

DeRenarardNez:

- Cold smoked duck. Per kilogram of meat - a tablespoon of salt, a tablespoon of lemon juice, ½ teaspoon of red pepper. Put a thoroughly washed and gutted bird under oppression for 48 hours in a cool place (2-4 ° C), after rubbing it with lemon juice and salt. To make the meat softer, I recommend to beat off the duck before salting. Press from above to break the bones and give a plane - so it will be better salted. After, before smoking, thickly roll in pepper outside and inside. The bird should be densely boned both outside and inside. Smoke the bird for 48 hours. It can be longer - you have to observe to understand how much. When smoking, I recommend using sawdust of oak, maple or cherry.

Pork tenderloin and brisket. For 5 kg of meat: a glass of salt, a tablespoon of sugar, ½ cup of lemon juice, a teaspoon of allspice, 4-5 chopped garlic cloves. The meat is rubbed with a mixture of salt, sugar and spices, aged in a cool place under oppression for 72 hours. Washed with cold water, dried and rubbed with lemon juice. The smoking time is from 24 to 48 hours (depending on the thickness of the pieces). The smoked ham is hung in a cool, dry place (1-4°C) for several days (as long as you can bear it) - it must dry out.

User Roman261076 mastered the cold smoking of fish, and having gained experience, he added lard and meat to the assortment. Here are his recipes for cold smoked smoke generators.

Roman261076:

- We clean the silver carp, take out the gills, rinse well and remove the black inner film. We salt with dry salting (the amount of salt per 10 kg of fish is 1.5 kg) and - under oppression, for 3-4 days. Take out and taste for salt. If the fish is too salty, soak and rinse. Soak at the rate of an hour per day of salting. Then we ventilate for 3-5 hours - and for smoking. The time of cold smoking of fish with a smoke generator on alder, oak and pear firewood and sawdust is usually a day at a temperature of 30 degrees. They also tried to smoke perch, catfish, small carp, pike.

How much to smoke cold-smoked fish with a smoke generator depends on the preparation. Product preparation is an important step. According to many members of the forum, it is better to salt and dry the fish for cold smoking beforehand - then it will not be smoked for a couple of days, but only about 12 hours, and this is not so long.