One of the components of the concept Vacation home- a stove and cozy warmth, while it is absolutely not necessary to start building a brick stove. Now for sale great amount metal stoves for the home, for every taste and income.

A compact, economical, energy-independent heating device - many people associate an iron stove for the home primarily with a potbelly stove. However, these powerful devices not only consume little fuel, but also heat the room perfectly.

Ovens to choose from

Modern stoves have many additional functions:

- temperature adjustment

- increased efficiency – the ability to choose a more efficient fuel, its complete combustion

- The equipment of many models allows not only to heat the room, but also to heat water, as well as to integrate the stove into the heating system of the house

- they can become very stylish decoration at home, some models are real works of art. Many metal home stoves are equipped with doors made of fireproof glass, which adds coziness to the home and allows you to admire the play of the flame.

Based on the fuel used, they can be divided into several groups:

- electricity

The most comfortable type of stoves are equipped with remote controls, temperature regulators, and control panels. However, if there is a power outage, there will be significant discomfort, and in addition, electricity bills will increase. These stoves are relatively inexpensive

Combustion regulation, a sensor system that ensures safety of use are also quite convenient option. However, if there is no gas installed in the house, there will be constant problem with filling of cylinders liquefied gas. Typically somewhat more expensive than electric ovens.

- firewood

Most popular look fuel, and at the same time the most romantic. It is the crackling logs that many buyers associate with a real stove, especially since you can buy a unit that imitates a fireplace. Many ovens have glass doors and forged elements. All models are designed so that the air in the room remains clean, and installation of these stoves is carried out in one day.

- fuel oil, diesel fuel, special compounds

Perhaps the cheapest of all types heating devices. Consume liquid fuel very economical, some models can operate on different flammable liquids.

What else should you think about when choosing a stove?

Having determined your preferred fuel, set of functions and appearance furnaces for the home made of metal, it is worth considering what power the unit needs.

Eat simple sign: the larger the firebox, the more powerful the stove. The output power will be approximately half the volume of the firebox in liters. You should also imagine how much area will be heated. For creating comfortable temperature on an area of 20 sq. m. you will need a unit with a capacity of 2-5 - 4 kW.

It should be borne in mind that these are mainly ovens long burning, which means continuous heat supply for 6-12 hours.

What to remember when installing a stove

A metal stove differs from a brick stove in the nature of the supplied thermal radiation. These are not soft waves, but a fairly hard current, which reaches a value of 500-6000.

The stove should be positioned taking into account cold air flows, so that it is convenient to supply fuel.

Don’t think that fires are only possible in wooden houses. Even concrete structures can catch fire, so consider all possible measures against fire safety is a very important task.

The floor must be covered with non-flammable material (metal, ceramic tile, asbestos board, etc.). in this case, the coating should be made larger than the perimeter of the oven by at least 50 cm.

Of course, the furniture will also have to be moved a considerable distance away, and the walls will have to be impregnated with fire protection and covered with insulating materials (after which they can be tiled, for example, the same as on the floor). In this case, the stove can be placed against the wall at a distance slightly less than required (meter). The furniture should be 60-80 cm away from the stove.

If you have no experience, it is better to entrust the installation of a chimney to professionals - it is important not only to install the chimney through the ceilings and roof, but also to prevent the wooden surfaces adjacent to the chimney from heating up. Moreover, from the correct established angles The tilt of the modules affects the thrust, and therefore the efficiency.

All requirements for the safe installation of a metal stove in the house are set out in detail in the documents for the products; they must be carefully studied, only after that you can begin to select a location for the unit and its installation.

Just a couple of decades ago, the entire choice of metal stoves came down to handicrafts of dubious performance. Modern market offers a variety of metal stoves for the home, among which you can find stylish multifunctional models that do an excellent job of heating rooms and look presentable. They are easy to install, easy to operate and maintain.

Manufacturers heating equipment They are constantly working to create new competitive models, improve the design, and equip the stoves with additional useful elements. Choosing a suitable stove is not easy, but if you take into account all the nuances and correctly calculate the required performance, you can get an economical and easy-to-use home heating system. So how to choose?

Beautiful arched stoves with glass doors fit perfectly into the design of country-style rooms

Why should you choose a metal stove?

There are five criteria that home owners follow when choosing metal models:

- efficiency;

- ease of installation and operation;

- durability;

- compactness, light weight;

- reliability.

Metal heating stoves for the home, they quickly warm up the air in the room. This is facilitated by design features: manufacturers set themselves the task of developing models that, when heated, create powerful convection currents. Due to this, the house quickly warms up. If earlier you could get badly burned on the stove body, now modern models Protective screens are provided that protect against injury and at the same time ensure even faster and more uniform distribution of heat.

Manufacturers try to equip their products so that stove buyers invest as little effort as possible in installing the equipment, and operation requires no effort at all. Metal models They are relatively lightweight and easy to transport and install. Thanks to their modest size, they take up little space and look good. If necessary, the structure can be dismantled without unnecessary labor costs and with a minimum amount of construction waste.

The main complaint about metal stoves is the rapid burning of wood and cooling of the premises. With the invention of long-burning stoves, the problem was solved. In one chamber, the fuel burns with limited access to oxygen, and the gas released during the smoldering process is burned in the other. This allows you to heat for 8-10 hours without adding firewood.

For the manufacture of modern furnaces, high-strength heat-resistant steel and cast iron are used. When choosing, you must pay attention to the manufacturer, the quality of the material, and the thickness of the metal. Heating equipment can last for decades. When buying, it is better to overpay a little, but buy a model High Quality, than save money and face the need to replace it in a couple of years.

Compact Finnish model in a modern minimalist interior

Types of metal stoves for home

Depending on the needs of the home owner, you can choose a model with necessary functions. There are these:

- Heating. They are intended exclusively for heating the home; they do not perform any additional functions. Some models are designed as fireplaces; they are often classified as a separate category.

- Heating and cooking. Can be used for cooking. Such models have kitchen stove, some designs even include an oven.

- Household. Such stoves are installed not only in residential premises, but also in bathhouses, garages, and utility rooms.

Models differ in heat capacity, efficiency, shape, design, and materials used. You need to choose taking into account all the features of the room in which the stove will be installed and its functionality. When calculating productivity, one should take into account not only the cubic capacity of the room, but also the degree of its thermal insulation, as well as climatic conditions.

Schematic illustration heating a house with a stove with a water circuit

Review of the most popular models

Having figured out the functionality and required performance, the home owner is faced with the problem of choosing a manufacturer and a specific model. You can only trust home heating to reliable companies that have been successfully competing in the heating equipment market for a long time. Imported models are usually more expensive, but better quality than their domestic counterparts. Russian stoves are attractive due to their price.

Heating stoves and fireplace stoves

These structures are easy to install, they quickly and efficiently warm up the house. The difference between a metal fireplace and a stove is the transparent door, which allows you to admire the view of the fire. Models with heat-resistant glass are more expensive than stoves with opaque doors, but look better in the interior. Most Popular:

- Vesuvius 150 kz. Economical domestic model with coil lining. The oven is made of high-quality steel with a thickness of 5 mm. The convenient ash drawer is designed so that it can be cleaned while the stove is heating. The door is cast iron, with glass, with self-cleaning and self-cooling systems. Top part The model gets very hot, so if desired, it can be used as a hob.

- Termofor-Butakov-Engineer. Model equipped cast iron door with glass and protective screen made of of stainless steel. Screens are less durable than the entire structure as a whole, and periodically need to be replaced, because they burn out, but they protect the convection pipes of the boiler well. The stove runs on coal. Manufacturer – Russia.

- THORMA Borgholm Keramik 950. Manufacturer – Slovakia. Furnace efficiency– 79%. The model is lined with tiles, very beautiful, practical and durable. The firebox is lined with fireclay and equipped with a firewood rack.

When choosing a stove, also pay attention to brand products La Nordica And Jotul. Each model of these brands is a real work of art. Cast iron elements are often stylized as forged, heat-resistant glass looks thin and weightless. External cladding invariably beautiful: designers work especially carefully decorative elements.

Metal wood burning fireplace Jotul F100BP – exquisite design, sophisticated decor, high efficiency

Heating and cooking stoves

Food cooked on a live fire always seems much tastier than on gas. If you are using a wood stove for heating, it makes sense to choose a model with a hob. We can recommend the following:

- Nordika Izotta. A unique model that combines the functions of a fireplace stove and a cooking stove. The increased volume of the firebox allows you to heat a room up to 280 m3. The body and cooking part are made of cast iron. The stove is aesthetically pleasing, reliable, and multifunctional.

- Fire-battery 7. Manufacturer – Russian company"Thermofor". Compact model equipped with a spacious firebox, a burner with two rings, and looks stylish. A thoughtful design allows you to achieve maximum efficiency of the furnace with a fairly modest size. You can adjust the burning intensity. The chimney is connected both from above and to the rear wall.

Heating and cooking stove with oven and firewood. The transparent door allows you to observe the fire and control the combustion process

Metal furnaces on solid fuel - the choice of people seeking to equip autonomous systems heating. The structures can be installed in any room. They are safe, reliable and will last for a long time. If you choose a model with a hob, fuel will be consumed with maximum benefit– both for heating and for cooking. Take a closer look, decide, buy. Let your home always be warm and cozy!

Video: metal stoves for baths and saunas

Any country house, even one intended for seasonal living, necessarily requires the presence of some kind of heating device. It can be used both for heating the room in the cold autumn-spring period, and for cooking and drying harvested fruits, mushrooms, as well as damp clothes or shoes.

Most often, stationary brick ovens are used for this, but their installation requires the construction of a separate foundation and installation of internal or external brick chimney, therefore, should be provided for at the design stage of the house.

Metal stoves for a country house

Many owners of country plots, when building a country house, did not think about building a permanent stove, so in such cases, in order to solve the heating issue, they use different kinds metal stoves that can be installed in finished house subject to compliance with fire safety regulations.

To help the reader understand this type of heating devices, this article will present brief instructions, which describes in detail the most effective types portable, designed for heating a small country house.

Main advantages

Despite the fact that such a structure is not capital, even with its small sizes, portable iron stove for a summer residence, in most cases it turns out to be quite effective, and in addition it has a number of positive qualities.

- Opportunity quick installation in any suitable place in a residential building without performing work on redevelopment of the premises.

- If necessary, for example in the warm season, it can be easily dismantled and stored in a barn, garage or attic.

- Due to the low heat capacity, energy is not wasted on heating the entire structure and the furnace heats up quickly, and accordingly the entire room.

- The relatively light weight of the structure does not require the construction of a capital foundation, and also contributes to significant fuel savings.

- Total price materials and cost of work are significantly lower than the cost of manufacturing a capital brick kiln.

- In the presence of hob can be used not only for heating the room, but also for heating or cooking food.

Advice!

If there is no stationary chimney in the house, chimney from a metal stove can be brought out into the window by first removing the glass from one sash and installing instead a metal plate with a hole of a suitable diameter.

Disadvantages of metal stoves

For all their positive qualities, metal heating and cooking ovens, unlike brick ones, they also have some disadvantages.

- Due to its low heat capacity, such a design cannot retain heat for a long time and requires constant heating to maintain the temperature.

- Due to the high heat transfer of the metal, the temperature of the external surfaces during operation reaches critical values, which can lead to a burn to the body or fire of surrounding objects, therefore the operation of such devices requires constant monitoring and very strict adherence to fire safety rules.

- When exposed to high temperatures, iron quickly oxidizes, so for the manufacture of furnaces it is necessary to use hardware significant thickness.

Potbelly stove for a summer residence

The most common option for metal furnaces for household use is a well-known potbelly stove. It is easy to manufacture, capable of a short time warm the air and maintain desired temperature in a heated room, and thanks to the presence of a hob, it makes it possible to heat or cook food.

One more positive quality What makes a potbelly stove is that it can run on almost any type of fuel.

If you have gas cutting and welding equipment, the simplest iron stove for your dacha can be made from a scrap of metal pipe with a diameter of 500 mm, a length of 800 mm and a wall thickness of at least 5 mm.

- At the bottom of the pipe, 20 mm from the edge using cutting torch cut a rectangular segment measuring 150x100 mm, which will serve as the blower door.

- Above it, at a height of 250 mm from the bottom edge, cut another rectangular segment measuring 240x200 mm, which will be used as a door for loading fuel.

- Inside the pipe, at a height of 200 mm from the bottom edge, weld a frame from a steel angle 25x25 mm, on which the cast iron elements of the grate will be laid.

- Weld round plugs with a diameter of 510 mm from sheet steel with a thickness of at least 5 mm to the lower and upper parts of the pipe. In this case, the top plug must have a hole for the exit of combustion products with a diameter of 100 mm.

- Weld to the bottom plug metal supports 80 - 100 mm high, and weld a metal pipe into the hole in the upper pipe to connect the chimney.

- Install on the blower and combustion opening using rotary hinges metal doors, which must be equipped with a locking mechanism.

The finished potbelly stove must be installed in the right place on a base made of non-flammable material(metal sheet, brickwork), lay grates inside, install an ash tray in the ash pit, and hermetically connect the chimney pipe to the outlet pipe.

Advice!

To check the tightness and primary burning of residual organic materials, it is recommended that the first heating of a new potbelly stove be carried out on outdoors in dry windy weather.

Metal fireplace

A more advanced version of metal country stove, which, in addition to its direct functions of heating the home, also has certain aesthetic qualities, can be called a light metal fireplace. Just like brick, it is heated with wood, but due to its light weight, smaller dimensions and mobile design, it can be installed indoors after the building has been built.

A modern metal fireplace is a high-tech design that has external thermal insulation and is manufactured in accordance with special calculations. Most often, its design uses elements of artistic forging, special smoke channels, equipped with dampers, and combustion doors, as a rule, are made of heat-resistant tempered glass.

Taking into account the above factors, when installing metal fireplaces Preference should be given to factory-made products.

Advice!

Thanks to high-quality thermal insulation of external surfaces and a well-designed smoke exhaust system, modern metal fireplaces can be safely heated as prefabricated ones. country houses from block containers, and small garden houses made of wood or brick.

Fire safety standards and regulations

Any metal stove in the house is a heating device increased danger Therefore, its installation and operation requires strict adherence to fire safety rules.

- Subfloor underneath heating device must be made of non-flammable material twice the size more area vertical projection of the furnace.

- Wooden surfaces must be located at a distance of at least 0.5 m from the side walls of the furnace, and they must be separated by a non-flammable screen thermal insulation material(mineral wool, asbestos sheet).

- Metal pipe The chimney must have double walls, between which a layer of mineral wool is laid.

- When a chimney passes through walls and ceilings in the opening, a fire-proof groove with a width of at least 200 mm is required on each side, which is laid mineral wool and is covered with a metal sheet.

- Before starting the stove for the first time, you must open all smoke dampers and make sure there is sufficient draft in the chimney.

- It is strictly forbidden to use gasoline, kerosene, acetone and other highly volatile and flammable liquids for ignition.

- During operation, the firebox door must be kept closed, and the level of air flow must be adjusted only with the help of a blower.

Advice!

During construction work, in the absence of electricity garden plot Renting a diesel generator for a dacha with a daily or monthly payment can help out.

Conclusion

After reading this article, it becomes clear that even in the absence of country house stationary stove heating, if necessary, at any time you can install a metal stove that runs on almost any type of fuel.

For getting additional information on this issue, you can watch the video in this article or read similar materials on this topic on our website.

DIY metal stoves

Bathhouse on own plot- this is an integral part of your country life. It can be large and beautiful, built in the form of a log house. You can order such baths, then they will be brought to your site and installed in a couple of hours. But if you are limited in funds, take everything into your own hands. After all, a small bathhouse can be raised from the materials left over from the construction of the main house. But in any case, whether you build a bathhouse yourself or have it built for you by professionals, the main element of such a building is the stove. And here in front of you stands one very important question. What to choose - a brick or metal stove for a summer residence?

The question is important, because even this seemingly not the most complex element requires certain financial investments for its construction. And again, if you are not limited in funds, then call an experienced stove maker who will make you a beautiful brick stove. If there are not so many funds, then best option- This is a metal stove of simple design. By the way, some models are easy to make with your own hands. But, of course, you must have skills in working with a welding machine.

But let's start our conversation with something else - with a comparison of brick and metal stoves for summer cottages. Why is this so important? The whole point is that brick kilns their design resembles metal ones. In any case, the principle of their operation is the same. Some models can be built with your own hands without calling a stove builder. Therefore, consumers sometimes face the question of choice - which stove is better? Let's try to figure this out too.

What's better?

Let's compare several positions that, in our opinion, are important:

- Operating principle. Metal stoves belong to the category permanent action. In order for them to continuously give off heat, they must be “fed” with fuel. Brick units are temporary heating devices. That is, they can be heated and fuel can be added little by little to maintain the required temperature. Sometimes for a certain period they are not heated at all, but due to the heat capacity brickwork the indoor temperature remains stable.

- Heating speed. Unfortunately, a brick stove is inferior to a metal stove in this category. In order for it to start releasing heat into the room, you need to burn the fuel for 2-3 hours. It all depends on the design. A metal stove is many times better in this regard. After just half an hour of operation, it heats up and begins to generate sufficient temperature. True, it cools down at the same speed.

- Safety. In this regard, a metal stove is clearly worse. Its walls become so hot that a fire can occur from a slight contact. That is why these models are necessarily reinforced in terms of fire safety with special screens made of non-combustible materials.

- Equipment price. It is clear here without words that brick version will cost much more. In addition, experts do not advise building it with your own hands. It is very difficult for an inexperienced person to ensure that the structure is 100% sealed. And the likelihood of incorrectly laid brickwork is too high. The same cannot be said about the metal counterpart.

- Heating area. In this position and brick construction, and metal are defined the same way. How bigger room for heating, the larger the oven should be. But you need to do some calculations first. Although large metal stoves used in dachas do not justify themselves in terms of fuel consumption. They "eat" too much.

Factory or homemade?

Since we started talking about metal stoves for the dacha, I would like to draw another parallel - compare factory-made products and home-made ones. Although such a comparison would probably be wrong. It's all about the quality of workmanship and the price of the equipment.

The price of factory-made devices is several times higher, the appearance of these units is better, and they differ in quality. And here homemade stoves characterized by low price. If they are made by a highly qualified craftsman, then the quality will be high. high level. Of course, in appearance they are inferior to the factory ones. But installing a protective screen can solve the problem if you use imagination and creativity in its manufacture.

And one moment. If we started comparing models, then to the end. Currently, the market offers home stoves made of cast iron and steel. It is impossible to make cast iron units with your own hands. This requires a casting process, which is organized at suburban area it is forbidden. For this it is necessary special equipment, in which the iron casting process is carried out.

Note that in terms of heat transfer, cast iron stoves are located between steel and brick. They don't heat up as quickly as steel ones, but they don't cool down as quickly either. In addition, we add that casting cast iron units allows you to show your imagination. Usually these stoves are beautiful with openwork decorative elements. Although the model line also includes devices that are simple in appearance and lower in price. Therefore, each consumer will find the necessary option for himself, both in terms of power and appearance - size and decor.

Economical metal stoves

Stove for a summer residence

The economic indicator of life today comes first. And we all try to save a little money. In this regard, careful fuel consumption is one of the important components. Of course, doing this in winter is problematic, because saving can worsen the quality of your stay. But if you approach the matter wisely, you can find some options here too. For example, pyrolysis models or long-burning solid fuel stoves.

Let's look at these positions individually. First, let's determine what the difference is between these two designs. Pyrolysis devices use the combustion principle flue gases, which in conventional models are simply thrown out into the street through the chimney. Therefore, in the design of such products, two combustion chambers are used - in the first, fuel is burned, and in the second, flue gases are burned. At the same time, the efficiency increases by 15%.

True, this design is not so simple. After all, it is necessary to install channels into the second combustion chamber through which fresh air will enter it, carrying oxygen to maintain combustion. Flue gases will not burn on their own, since this requires enriching them with oxygen. And only an air-gas mixture, where both materials are mixed in certain proportions, will burn efficiently, releasing sufficiently large thermal energy.

Therefore, when making iron stoves for the home, you need to take care of the drawings - fortunately they are in free access in the Internet. By the way, pyrolysis furnaces can operate on any type of fuel, and this is their big advantage.

Metal wood stoves

Wood heating stove

So, we have come to an option that is not used very often in country houses today, because the fruits of civilization are gradually reaching the most remote areas. But wood stoves are traditional heating units, which are still quite popular today for heating cottages, bathhouses, garages and other outbuildings. But again the question of an economical approach to the use of fuel resources arises.

Of course, firewood is the cheapest fuel material today, but its irrational use can lead to large financial costs. So you have to save money here too. Therefore, we offer so-called wood stoves long burning.

What is the principle of their operation?

- Firstly, the combustion process occurs when oxygen is consumed in small quantities. That is, in the combustion zone, the firewood smolders, while releasing enough a large number of thermal energy. By the way, many models of this design are additionally equipped with a second firebox, where waste products are burned. carbon monoxide. That is, this combined option, where two processes are used - wood smoldering and pyrolysis.

- Secondly, the fuel has to be placed in a certain way so that between its elements there is as much space as possible. less space. When it comes to firewood, they are stacked in rows or in the form of a cage. It is important here not to leave space between the logs. The denser the bookmark, the longer it burns. By the way, if you place firewood in the firebox correctly, it can smolder for up to 24 hours. And this is already an indicator of ease of use.

- Thirdly, fresh air from outside is not supplied to the combustion chamber itself, but to the area where smoldering occurs.

These are the iron stoves for an economy class home that can be used today in summer cottages. Many craftsmen make them with their own hands, but factory-made versions can also be found on sale in a wide range.

Chimney for a metal stove

Stove for a summer residence with a chimney

This outlet pipe plays a special role in the design of a home furnace. With its help, not only the products of fuel combustion are removed, but also a draft is created, which affects the quality of operation of the heating unit and its efficiency.

What are the requirements for a chimney?

- There are two types of chimney pipe design - round and rectangular. Give preference to the first, because turbulence can form in the corners of a rectangular cross-section, which reduces traction. In addition, this type of section does not really justify itself in terms of effective removal carbon monoxide. In this case, the optimal cross-sectional area of the chimney is 1.5 times the area of the pipe coming out of the stove for a summer residence.

- The ideal option is if the pipe has a minimum number of bends. And it’s even better if she doesn’t have them at all. It is taken outside the building 1.5 m above the roof ridge.

- The pipe can be made from galvanized or stainless steel, ceramics or glass. Three latest material have long term operation, which is an important indicator today. True, their cost is several times higher than that of products made from ordinary or galvanized metal sheet. By the way, quite recently they were used asbestos pipes, but their age has already passed.

- At the design stage metal stove For a dacha, the installation location of the chimney itself is precisely determined. In this case, it will be a fundamental element. First, a chimney is installed, and then a stove for the home is connected to it. This is why choosing the right location is so important.

- When it comes to long-burning heating devices, the chimney for them should not be installed strictly vertically, but horizontally with a slight upward slope. In any case, the horizontal part of the pipe should not be less than three meters.

- In uninsulated attic rooms, the chimney must be insulated using modern heat-resistant materials.

Conclusion on the topic

Iron stoves for the dacha are represented by a huge model range. From it you can choose the model that, according to your requirements, will exactly fit into a country house, bathhouse or other utility room.

Today, such products are subject to fairly stringent requirements, the main ones being operational safety and fuel economy. The modern market is oversaturated with this type of equipment, so every consumer will find a factory or homemade version. It is only important to approach the choice correctly.

In our age high technology and new technical solutions, the concepts of many traditional heating devices who came to us from the past. These changes also affected wood-burning stoves. It would seem like a simple product made of brick or metal, what else can you come up with? It turned out that it is possible. The “potbelly stoves” that are familiar to us have especially changed, both externally and internally. Now these are modern wood-burning heating stoves, which are very popular due to their low cost.

Steel Wood Stove Upgrades

Homemade “potbelly stoves” can now only be found in someone’s garage or in another utility room. These very simple direct combustion stoves burned wood at a terrible speed, throwing out the bulk of the heat into the chimney. For this reason, people using “potbelly stoves” tried to make the horizontal section of the chimney pipe as long as possible, passing it through the entire room. The goal is to take away maximum heat from combustion products that fly out of a wood-burning stove at a temperature of 400-500ºC.

![]() Nowadays, every modern stove for heating a private home bears little resemblance to a “potbelly stove”, as it is equipped with a decorative protective casing with air holes, or the combustion chamber body is surrounded by air duct pipes. There are reasons for this, the first one is heat surface makes the heater dangerous for residential premises where people and children are constantly present, who can accidentally get burned. In addition, hot metal surface produces a powerful heat flux that exceeds the norm. The casing receives hard radiation and, heating up, transfers heat to the air of the room.

Nowadays, every modern stove for heating a private home bears little resemblance to a “potbelly stove”, as it is equipped with a decorative protective casing with air holes, or the combustion chamber body is surrounded by air duct pipes. There are reasons for this, the first one is heat surface makes the heater dangerous for residential premises where people and children are constantly present, who can accidentally get burned. In addition, hot metal surface produces a powerful heat flux that exceeds the norm. The casing receives hard radiation and, heating up, transfers heat to the air of the room.

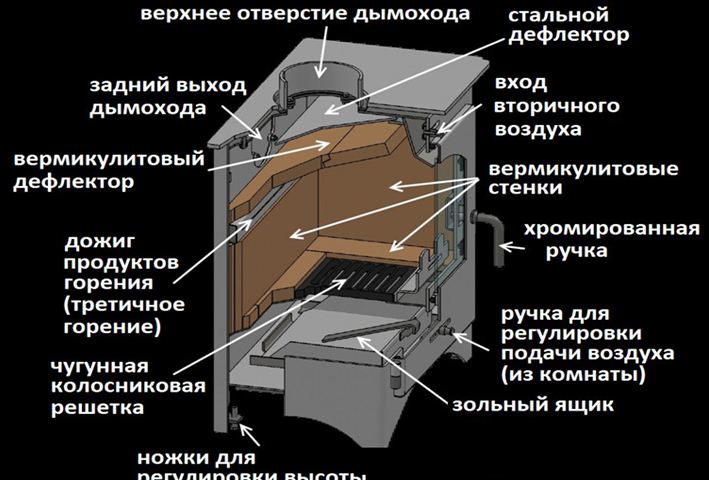

Due to the introduction of new technical solutions, the designs of wood stoves have also changed. Briefly, the changes are as follows:

- Admission fresh air for combustion in the firebox has become adjustable.

- Several partitions are installed above the combustion chamber, which is why flue gases can no longer fly straight into the chimney. First, they give up their heat, making several moves inside the heater and going around these partitions.

- To increase the service life of their products, many manufacturers line the fireboxes of steel furnaces with refractory bricks.

- Afterburning of the released pyrolysis gases is organized.

- The hob is made of steel or cast iron.

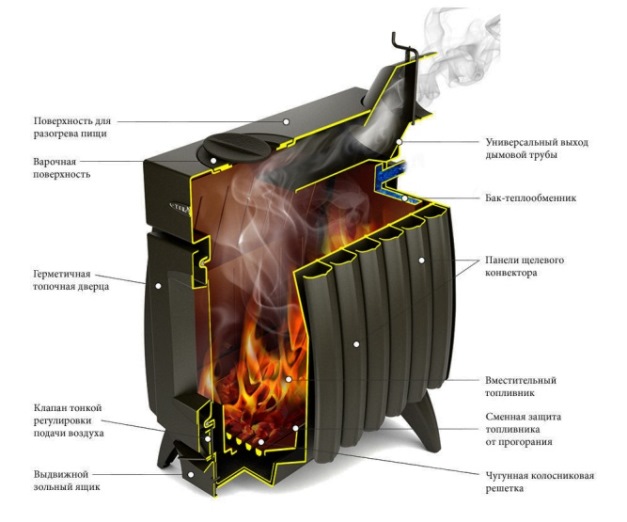

- Some models have heat exchangers installed to heat water for domestic hot water needs.

- An innovative solution has been implemented - a simple wood stove generates electricity.

Overview of types of stoves

At the moment, there are 2 main types of heating wood-burning stoves made of metal:

- classic, direct combustion;

- long-burning heating devices.

In devices of the first type, fuel no longer burns as quickly as in a “potbelly stove”, since access to fresh air is limited, and the gases intensively give off heat metal walls. An example would be a wood-burning steel stove for a sauna.

The red arrows in the diagram show flue gases making an additional move before escaping into the chimney channel. As a result, their outlet temperature rarely reaches 200ºС, and in some units you can even touch the pipe with your hand right during operation. This suggests that the bulk of the thermal energy released during combustion hard species fuel remains in the room, and the efficiency of the heaters reaches 70%.

As in modern pyrolysis stoves, some models of stoves are designed to slowly burn wood with insufficient oxygen. As a result, pyrolysis gas is formed, which is burned using a point supply of air to the upper zone of the combustion chamber. Shown below is a wood burning gas stove.

An injector is located in the upper zone of the combustion chamber, which ensures the supply of secondary air, as a result of which the pipes - air ducts are evenly heated from top to bottom. Air enters them through the lower openings, passes through curved pipes, heats up in the firebox, and exits into the space of the room. At the same time, wood combustion occurs slowly; one load can be enough for 6-8 hours of continuous operation. Accordingly, the requirements for fuel quality are quite high; firewood can be used with a moisture content of no higher than 25%, otherwise the pyrolysis process will not take place.

Essentially modernized steel furnaces by its design and additional functions not much different from boilers. The only difference is that the stove uses the phenomenon of convection to heat rooms, heating air rather than water. However, a wood heating stove with a water circuit has already appeared that can be connected to DHW system or organize a small water heating Houses.

This is not traditional water jacket, as in boilers, here the water in the tank is heated from back wall combustion chambers. In addition, at the top of the product there is a hob for cooking. For more complete heat transfer under hob a partition is installed and the flue gases have to go around it, making a second additional move.

Newly developed steel furnaces

Deserves special attention a unit that, like a bell-type heating stove for a brick cottage, uses the principle of free convective movement flue gases along the channels, right up to the chimney.

This stove is more efficient compared to its “brothers”; instead of a hob, it has an oven design open type, located directly above the cap. Even if the firebox is extinguished, food left in the oven niche will not cool down for a long time. Well, the door of the main firebox, through which firewood is loaded, opens to 140º and is equipped with a large fireproof glass and resembles a heating fireplace.

The line of portable direct combustion units is of considerable interest Russian manufacturer TERMOFOR. One of them is the small-sized wood-burning heating and cooking stove Cinderella. With its modest dimensions of 465 x 300 x 460 mm and a weight of 27 kg, it has thermal power 4 kW and can heat a room up to 50 m2. This heater can safely be considered portable and can be used in almost any conditions, although its remarkable appearance allows the stove to be placed in a residential building.

Other original product from the same line - a wood-burning heating and cooking stove Indigirka. If you have never charged your cellular telephone from a wood stove, then Indigirka will help you. It has a built-in block - an electricity generator, which literally immediately after kindling produces a voltage of 12 V and has a power of up to 75 W.

Oven Indigidka

Thanks to their updates, once simple wood-burning stoves for a summer house or garage have turned into serious heating units used to heat residential and any other premises. At the same time, they remained very attractive due to their low cost and small volume. installation work on their installation.